In modern industrial facilities, fluid transfer is not only limited to ensuring the continuity of production; it also plays a critical role in the overall safety of the facility, its environmentally compatible sustainability, and energy efficiency. As production processes become increasingly complex, precise, and versatile today, it may be necessary to transport fluids with very different chemical and physical properties in industrial infrastructures. These include flammable, explosive, toxic, corrosive, viscous, or high hygiene standard liquids such as food/pharmaceuticals. The safe, efficient, and uninterrupted transfer of these fluids, each with its own risks and requirements, is extremely important in terms of both occupational health and safety and process quality.

While traditional electric motor pumps offer a suitable solution for certain applications, they can lead to serious limitations and risks in the transfer of explosive or hazardous chemicals, high-viscosity or particle-containing liquids. The risk of electrical sparks, motor overheating, or potential electrical failures can be one of the main causes of major accidents and production stoppages, especially in hazardous environments such as chemical, petroleum, pharmaceutical, paint, mining, and energy. Additionally, the structural and material durability of standard pumps may be insufficient for many corrosive or aggressive chemicals, leading to frequent failures, high maintenance costs, and prolonged downtimes.

However, both national and international regulations and safety standards demand much stricter and advanced measures in equipment used in facilities with ex-proof (explosion-proof) requirements. The increasing regulatory pressure and the necessity for sustainable production have led businesses to seek innovative, safe, and versatile solutions in pump technologies.

At this point, air diaphragm pumps are almost a turning point for contemporary industrial facilities. These systems, which operate solely with compressed air, completely eliminate risks such as sparks, electrical arcs, or motor overheating during the process. With these features, they respond at the highest level to both legal requirements and operational safety in the transfer of flammable and explosive substances. Especially in environments where fuel, thinner, solvent, alcohol, and other hazardous chemicals are transported, air diaphragm pumps serve not only as equipment but also as insurance for the safety of the facility and employees.

Beyond this, the high flexibility and practical use of air diaphragm pumps provide great advantages in industrial processes. Thanks to the easy adjustability of air pressure, the pump output pressure and flow rate can be brought to the desired value by the operator within seconds. Sudden process changes or different fluid needs in the system can be quickly responded to. Their tolerance to dry running ensures that the pump is not damaged even in tank or pipe emptying, reducing the need for maintenance and repair and guaranteeing uninterrupted production. Additionally, with different material options (PTFE, EPDM, Viton, stainless steel, etc.), they can adapt to both abrasive chemicals and hygiene-required food and pharmaceutical applications.

Today, air diaphragm pumps have become indispensable equipment for transfer, filling, circulation, and dosing operations across a wide range of industries, from the chemical and petrochemical industry to the food and beverage sector, from pharmaceutical and cosmetic production to mining, automotive, water treatment, and maritime applications. With low maintenance requirements, long life, a wide range of chemical compatibility, practical installation, and ease of operation, they offer significant advantages to businesses in terms of both efficiency and total cost of ownership.

In conclusion, the key to safe, sustainable, and flexible fluid transfer in modern industry lies in air diaphragm pump technologies. With advanced safety, process flexibility, and low maintenance needs, air diaphragm pumps form the foundation of operational success and competitive advantage for businesses of all sizes.

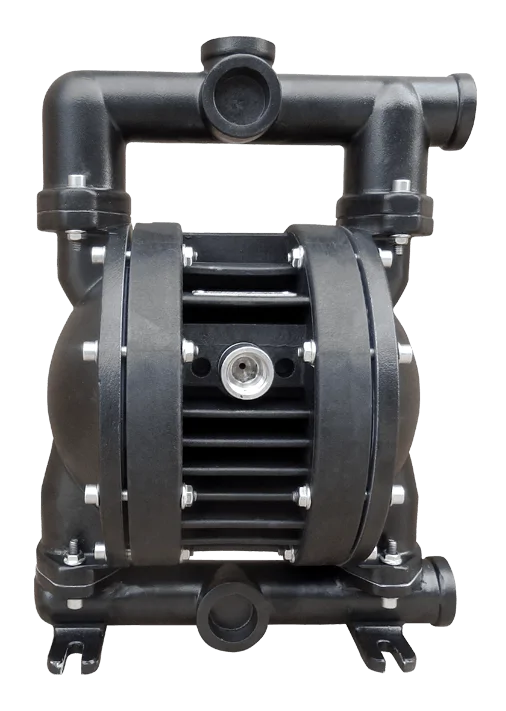

Air diaphragm pumps stand out as the modern member of the "positive displacement pump" family in the industry, requiring high safety and flexibility. Although their working principles resemble the logic of old-style hand pumps, their technological structures and application areas are far superior to classical solutions. Their most distinctive feature is that they provide all their driving power entirely with compressed air. Thus, they do not require any electric motor, belt, gear, or complex mechanical drive system. They can operate long-term and safely in facilities with only a compressed air line and compressor support.

The main structure of the pump consists of two flexible diaphragms placed opposite each other on the sides of the body. These diaphragms are usually made of elastomers with high chemical and mechanical resistance or special polymers like PTFE. The air direction valve (air distributor) located at the center of the pump, which acts as the "brain" of the pump, automatically directs the compressed air given to the system sequentially to one diaphragm and then to the other. When compressed air comes behind one diaphragm, the diaphragm moves forward and pushes the liquid in the pump body towards the discharge line. At the same time, the diaphragm on the opposite side retracts with the evacuation of the air behind it to the atmosphere, creating a vacuum inside the body. This vacuum effect allows the liquid to be drawn from the suction line. In the next cycle, the air direction valve switches to the opposite side, roles change, and the cycle is continuously repeated automatically.

This double diaphragm and valve architecture allows the pump to transfer the liquid efficiently and precisely with each stroke. Since the fluid only contacts the diaphragm and body inside the pump, even abrasive, particulate, or reactive chemicals can be pumped safely. The check valves located at the pump inlet and outlet guarantee that the fluid moves only in the correct direction; thus, unwanted situations such as backflow or leakage are completely prevented. Additionally, the valves' resistance to clogging and ease of assembly and disassembly support the pumps' long life in challenging and uninterrupted processes.

The pump's output flow rate and pressure are adjusted directly based on the air pressure and flow given to the system. The user can precisely change the pump's capacity according to the system's needs in real-time with an air regulator or valve. This situation makes it possible to quickly adapt to changing process conditions or different liquid types on production lines. While additional control units or inverters are required for speed or pressure changes in classic electric motor pumps, it is sufficient to intervene only in the air source in air diaphragm pumps.

Another technical advantage is that there is no direct contact between the fluid and moving metal or complex mechanical components in air diaphragm pumps. Since the liquid only contacts the diaphragm and body, wear or rusting of the pump's internal components is minimized. This structure significantly reduces maintenance costs, especially in corrosive, abrasive, high-viscosity, or solid particle-containing fluids. Additionally, by selecting diaphragms (PTFE/Teflon, Santoprene, Viton, EPDM, etc.) and valve materials suitable for different fluids, long-lasting and safe transfer is ensured in a very wide range of applications, including acids, bases, solvents, oils, polymers, or particle-dense mixtures.

Furthermore, the low dead volume in the internal design of air diaphragm pumps and their ease of cleaning make them preferred in food, pharmaceutical, and cosmetic applications requiring hygiene. Moreover, these pumps are tolerant of short-term dry running; that is, when the suction line is emptied of liquid, they do not immediately fail like electric pumps, and the diaphragm can continue to operate for a while without damage.

In conclusion, the working principle and structure of air diaphragm pumps offer an unrivaled solution in industrial applications with advantages such as high safety, independence from electricity, precise flow and pressure control, low maintenance needs, and versatile chemical compatibility. This technology provides businesses with a guarantee of safe, economical, and sustainable operation for many years, even in the most challenging and critical fluid transfers in sectors such as chemicals, petrochemicals, food, pharmaceuticals, paint, treatment, and mining.

Advantage of Non-Electric Operation and Explosion-Proof (Ex-Proof)

One of the main reasons air diaphragm pumps are so valuable and preferred in the industry is that there is no electric motor, spark-producing component, or part in contact with electricity in their working principles. All movement and fluid transfer of the pump occur solely with compressed air. This completely isolates all electrical hazards, especially in environments with explosion risks, from the system and creates a great advantage in terms of facility safety.

For many industrial facilities, the transfer of easily flammable substances with low flash points, such as solvents, thinners, gasoline, diesel, alcohol, and various chemicals, poses a significant safety risk. Traditional electric motor pumps can pose a significant danger, especially in such environments. The slightest electrical spark, short circuit, motor overheating, or insulation failure can lead to a chain explosion that can damage not only the equipment but the entire facility. Moreover, this risk continues during maintenance or in case of a malfunction.

The completely non-electric structure of air diaphragm pumps makes them naturally the ideal solution in environments requiring ex-proof (explosion-proof) conditions. Since there is no electrical equipment or cable in the system, the formation of electrical arcs or sparks is completely eliminated. This allows international explosion protection standards such as ATEX, IECEx, and UL to be fully implemented in facilities. Air diaphragm pumps easily comply with all certifications sought for equipment used in such explosive environments, thus meeting legal and technical requirements easily. Especially in large volume storage, tank farms, ship and port loading areas, fuel stations, or chemical/petrochemical refineries, working without these certifications means serious sanctions and high insurance costs.

In the chemical and petrochemical industry, not only safety but also continuous and efficient operation in the process is critical. Air diaphragm pumps provide safe transfer and dosing 24/7 without electrical failures, power outages, lightning strikes, or electrical risks during maintenance. Therefore, air diaphragm pumps have become indispensable equipment, especially in lines where explosive gases, solvents, resins, and flammable liquids are transported, in the paint and varnish industry, pharmaceutical production, mining, port, dock, ship, and fuel loading/unloading operations.

The advantage of not operating with electricity not only stands out for fixed facilities but also for mobile applications, temporary field installations, and environments where power outages are frequent. For example, in many temporary or mobile applications such as emergency evacuation, environmental cleaning, container transfers, and liquid transfers within ships, it is possible to immediately activate the pump without the need for an electrical infrastructure.

By eliminating the danger of electrical sparks and arcs, not only the working personnel but also the general operational safety of the facility and the integrity of the equipment are protected at the maximum level. Additionally, this ensures compliance with insurance requirements, facilitates regulatory compliance, and reduces operating costs in the long run.

In short, thanks to these versatile safety and operational advantages, air diaphragm pumps have become not just equipment in modern industrial fluid transfer but almost the heart and safety insurance of the facility. When advanced safety requirements, explosion-proof standards, and flexible field applications are concerned, air diaphragm pump technology is solidifying its place in the industrial world day by day.

High Flexibility: Flow and Pressure Adjustment, Dry Running Capability

One of the main reasons air diaphragm pumps are so widely and reliably preferred in industrial applications is the unique operational flexibility they offer. According to the system's needs, the pump's output flow and pressure can be easily adjusted within seconds through an air regulator or valve. At this point, there is no need for a motor control panel, frequency inverter, or electric speed switch; rapid response to process requirements can be achieved through a single air line connection. Thus, the same pump can be used both in high-volume fillings and in low-flow precise dosing in the production field, adapting to different operational requirements.

This high flexibility offers operators a great advantage against fluctuations and changes encountered in modern production lines. For example, in the chemical industry, during a tank filling, high flow may be needed first for fast filling, and then low flow for precise volume control and overflow prevention. The same pump can meet these different needs within seconds by simply changing the air pressure and flow. In the food or pharmaceutical industries, products of different densities and viscosities can be processed with the same system; there is no need to change equipment as the process changes.

Another important advantage is the deep suction capability. Thanks to the diaphragm structure of air diaphragm pumps that can create high vacuum, there is no need for the liquid to flow by gravity in the suction line. In other words, the pump can easily draw liquid from barrels, IBC tanks, or underground storage units below ground level. This provides great convenience, especially in field applications, environmental cleaning operations, and process residue evacuation. The advantage provided by air diaphragm pumps in many critical applications such as fuel extraction from underground tanks at fuel stations, liquid/sludge evacuation in mining, and waste barrel emptying in chemical factories plays an important role in terms of operational efficiency and safety.

Another critical feature of air diaphragm pumps is their tolerance to short-term dry running. When there is no liquid left in the suction line, immediate failure or damage does not occur as in electric or mechanical pumps. The diaphragm pump can operate for a short period without damage; this minimizes the risk of pump damage, especially when the tank or barrel is completely emptied or the fluid level suddenly changes. It prevents operator errors and reduces the need for unplanned maintenance. However, it should be noted that long-term dry running can shorten the diaphragm's life; therefore, by design, this feature is ideal for "short-term" emergencies or transition scenarios.

Moreover, air diaphragm pumps can effectively transfer fluids with different viscosities, liquids containing particles or sludge, and even mixtures containing solid matter at certain concentrations. This versatility provides significant advantages, especially in treatment plants, waste management, and the chemical and paint industries. Since there are no moving metal parts inside the pump, the risk of clogging and wear is minimized; maintenance intervals are extended, and operating costs are reduced.

Additionally, at the beginning of the process, during rinsing or system cleaning, it offers great convenience to operators; the pump can be easily cleaned and tolerates short-term start-stop operations. All these technical advantages make air diaphragm pumps one of the most preferred pump types in modern industry in terms of both safety and productivity. With flexible capacity adjustment, strong suction capability, resistance to dry running, and compatibility with different types of liquids, air diaphragm pumps stand out as a reliable solution in the changing and challenging conditions of businesses.

Wide Usage Areas in Different Industries

Thanks to their technical superiority and flexible design options, air diaphragm pumps are widely used in almost every industrial field today. Their features such as chemical resistance, explosion-proof, low maintenance requirement, and ability to easily transfer fluids with different viscosities and particle structures put them a step ahead of classic pump types.

Chemical Industry: The chemical sector requires the safe and leak-proof transfer of acids, bases, solvents, resins, and aggressive chemicals. Air diaphragm pumps are intensively preferred in chemical facilities where the use of electrical equipment is risky, both with their ex-proof structures and chemical-resistant body and diaphragm options. With diaphragm materials such as PTFE (Teflon), Viton, EPDM, or Santoprene, acidic, basic, or solvent-featured liquids can be safely transferred.

Food and Beverage Industry: In the food and beverage sector, where hygiene standards must be at a high level, air diaphragm pumps offer advantages in terms of both product safety and ease of cleaning. Thanks to stainless steel bodies, food-compatible elastomer diaphragms, and easily disassembled modular designs, juices, milk, syrup, concentrates, and various beverages can be pumped hygienically. They are also an ideal solution for tank or pipe cleaning without leaving product residue.

Pharmaceutical and Cosmetic Industry: In pharmaceutical and cosmetic production lines requiring precise dosing and high product purity, air diaphragm pumps minimize the risk of contamination. With their hygienic design, ease of sterilization, and compatibility with particle transfer, both semi-solid and liquid products such as creams and syrups are safely transferred. Maximum accuracy is achieved in dosing operations with low vibration and precise flow control.

Wastewater Treatment and Environmental Technologies: In wastewater treatment plants, the transfer of sludge, sediment, and fluids containing high solid matter is often challenging. Air diaphragm pumps can operate long-term without the risk of clogging in pumping water containing large particles, fibrous material, or dense sludge. They are also preferred in treatment processes due to their ease of maintenance and high durability.

Mining and Heavy Industry: In the mining sector, air diaphragm pumps are ideal for transporting dense, muddy, abrasive, and particle-laden fluids. They can be used in both mobile applications and fixed stations; they offer the advantage of safe operation even in explosive environments.

Paint, Varnish, and Paper Industry: In sectors such as paint, ink, varnish, and paper production, air diaphragm pumps can easily transfer high-viscosity and particle-containing fluids. Their non-electric structure provides safe solutions in explosive gas atmospheres. They also offer precise dosing and ease of cleaning during product transfer.

Automotive and Metal Industry: In the automotive industry, they are intensively used in the transfer of chemical baths, paint lines, lubricants, coolants, and cleaning fluids; in the metal processing industry, they are used for the transportation of acids, oils, chip fluids, and chemical wastes.

The common advantages of air diaphragm pumps in all these sectors are:

• Low maintenance and long service life

• Wide range of chemical compatibility

• Easy adaptation to every fluid type in the system with different body, diaphragm, and seal material options

• Quick installation and cleaning

• Naturally meeting ex-proof (explosion-proof) requirements

• Easy use in mobile or fixed facilities

With different elastomers such as PTFE, EPDM, Viton, Santoprene, and stainless, aluminum, or plastic body options selected according to the system, air diaphragm pumps offer safe and efficient operation even in the most challenging processes. Thanks to this versatile structure, air diaphragm pumps have become one of the most preferred equipment in industrial fluid transfer today.

Conclusion: The Key to Safe and Flexible Pump Solutions

Air diaphragm pumps provide a unique response to the increasing demands for safety, flexibility, and cost-effectiveness in today's industry. Considering the diversity in industrial processes and changing working conditions, air diaphragm pump technologies are increasingly preferred to overcome many challenges encountered in both newly established and existing production lines. Their ability to operate solely with compressed air without the need for electrical connections makes them indispensable equipment for hazardous environments and processes requiring explosion-proof conditions. In this way, they not only increase process efficiency and occupational safety but also contribute to businesses' sustainability goals by fully complying with national and international standards and legal regulations.

The high safety standard provided by air diaphragm pumps is of vital importance, especially in risky sectors such as chemicals, petrochemicals, paint, pharmaceuticals, mining, and energy, where flammable and explosive liquids are transferred. The complete elimination of dangers such as sparks, short circuits, or overheating that may arise in electric motor pumps elevates the safety of both facilities and employees to the maximum level. Moreover, being able to provide safe liquid transfer without electrical risk and without having explosion-proof equipment is one of the most important advantages of air diaphragm pumps.

In addition, the flexible operating features and easily adjustable capacity of air diaphragm pumps make it possible to respond to many different process needs with a single piece of equipment. By increasing or decreasing the air pressure, the flow rate and output pressure can be changed within minutes, allowing operators to easily manage different fluids or variable flow needs on the production line without the need for additional equipment. Additionally, the ability of the pumps to perform deep suction and their resistance to short-term dry running reduce the margin of error in tank emptying, barrel filling, or circulation operations and increase process safety. During short-term dry running, the pump is not damaged, and this feature provides a great advantage, especially in automated systems or processes with frequent start/stop operations.

Thanks to the option of chemically resistant diaphragm, seal, and body materials, they offer an ideal solution for all aggressive, abrasive, particulate, hygienic, or sensitive liquids. In sectors where the highest hygiene standards are sought, such as food and pharmaceuticals, they can be used seamlessly with stainless bodies and food-compatible elastomers. In wastewater treatment plants, they stand out with high durability and low clogging risk in the transfer of sludge and sediment containing high particles.

Air diaphragm pumps provide significant economic contributions to businesses not only with their technical advantages but also with their low maintenance needs and long life. The absence of wearing and maintenance-requiring parts such as electric motors, gears, or seals minimizes service and spare part costs. Thanks to their easily cleanable modular designs, maintenance operations can be carried out quickly and practically, preventing production losses.

In conclusion, air diaphragm pumps stand out as one of the most rational solutions for safe, flexible, economical, and long-lasting fluid transfer in modern industry. With the appropriate capacity and material selection, professional installation, and regular maintenance, these pumps become a strong investment that increases the competitiveness of businesses, guarantees production continuity, and ensures process safety. For facilities of all sizes and all types of processes, air diaphragm pump systems will continue to be a fundamental building block in the vision of sustainable and trouble-free production of the future.