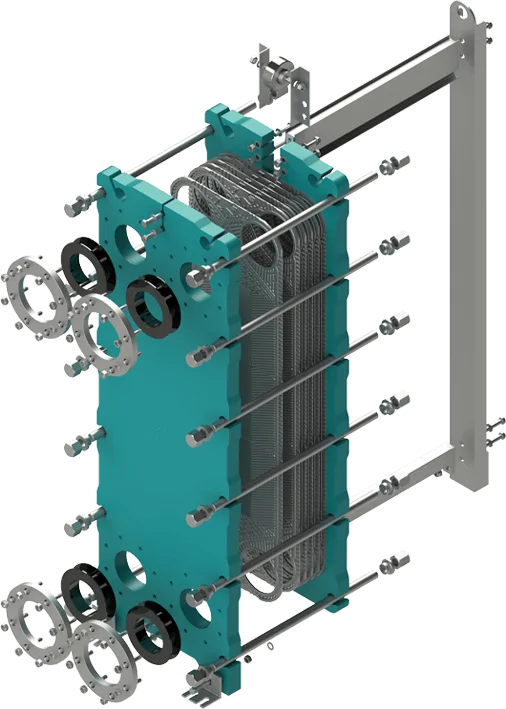

Plate heat exchangers are high-efficiency and compact heat exchangers that provide heat transfer between two different fluids without direct contact. Their basic working principle is based on the heat exchange created by hot and cold fluids passing through thin metal plates arranged in parallel. This structure allows for a high heat transfer surface and minimizes the size of the device.

These plates, usually made from materials with high thermal conductivity and corrosion resistance such as stainless steel, titanium, or nickel alloys, create narrow channels between them, allowing fluids to flow turbulently. Turbulence increases the heat transfer coefficient and enhances system efficiency.

One of the most important advantages of plate exchangers is that they offer much higher heat transfer efficiency compared to other types of exchangers. The thin structure of the plates accelerates heat transfer between the two fluids and minimizes energy losses. At the same time, their compact structure saves space, which is a major advantage, especially in cases where facility space is limited.

These devices are not limited to heating and cooling processes but can also be used as circuit separators, pressure breakers, or heat recovery elements. They extend the lifespan of the system they are used in, reduce energy consumption, and offer ease of maintenance. With these features, plate heat exchangers are critical components preferred in a wide range from industrial facilities to residential areas, at the heart of modern energy management solutions.

The working principle of plate heat exchangers is based on the counterflow of hot and cold fluids in narrow channels between the plates without contacting each other. This arrangement ensures highly efficient heat exchange. Since the fluids do not come into direct contact, the risk of mixing is eliminated, and system safety is increased.

The plates at the core of the exchanger have specially designed wavy or embossed surfaces. This surface geometry allows the fluid to move turbulently along the plate. Turbulence causes the fluid to contact the surface more, significantly increasing the heat transfer coefficient. It also prevents sediment buildup on the plate surface, maintaining system efficiency for a long time.

The working process generally proceeds as follows: the hot fluid enters through the inlet line and transfers its heat to the plate as it passes through the plate channels. Simultaneously, the cold fluid flowing in the opposite direction advances through its line and absorbs the heat from the plate, raising its temperature. This counterflow arrangement maximizes the temperature difference, increasing heat transfer efficiency.

The high efficiency in plate exchangers is directly related not only to the direction of fluid movement but also to the number and arrangement of plates. The heat transfer capacity can be increased by adding more plates according to system requirements. This feature allows the exchanger to be easily adapted to different flow, temperature, and pressure conditions.

Additionally, the proper adjustment of the inlet and outlet temperatures and flow rates of the fluids directly affects exchanger performance. In a well-designed system, energy losses are minimized by optimizing the time and contact area the fluids spend passing through the plate. This reduces operating costs while increasing the overall efficiency of the system.

In conclusion, the working principle of plate heat exchangers creates a highly efficient, safe, and sustainable heat transfer process through the combination of turbulent flow, a wide heat transfer surface, and counterflow fluid movement. This structure makes plate exchangers indispensable in many areas, from modern industrial facilities to energy recovery systems.

Advantages of Plate Heat Exchangers

Plate heat exchangers offer many important advantages compared to other types of heat exchangers due to their innovative design and engineering features. These advantages not only increase energy efficiency but also reduce operating costs, extend system lifespan, and contribute to sustainability goals.

High Heat Transfer Efficiency

The most prominent advantage of plate exchangers is their exceptionally high heat transfer coefficients. The large surface area of the plates and the turbulent flow design ensure maximum contact of the fluids with the plate surface. This increases the rate of heat transfer and minimizes energy losses during transfer. Their ability to be produced in much smaller sizes with the same capacity compared to traditional tubular exchangers provides a significant advantage in system design.

Compact and Lightweight Design

Plate exchangers stand out by offering high efficiency in compact sizes. Since a large surface area is gathered in a small volume, the devices take up much less space. This feature provides a major advantage, especially in industrial facilities and machine rooms where facility space is limited. Additionally, their lightweight structure allows for easier and faster transportation, installation, and maintenance operations.

Flexible and Scalable Structure

Plate exchangers can be easily adapted to different applications thanks to their modular structures. The heat transfer capacity can be adjusted by adding or removing plates according to needs. Thus, the system's capacity can be increased or decreased, and it can quickly adapt to new process conditions. This feature provides significant flexibility for businesses planning future capacity increases.

Easy Cleaning and Low Maintenance Requirement

Since the plates of plate exchangers can be easily disassembled and reassembled, cleaning and maintenance operations become quite practical. This ensures that regular maintenance intervals are completed in a short time and minimizes downtime. Additionally, the removable structure of the plates allows only the relevant plate to be replaced in case of a possible leak or malfunction, significantly reducing maintenance costs.

Energy Efficiency and Reduction in Operating Costs

Plate exchangers perform more heat transfer with less energy due to their high efficiency. This reduces operating costs, especially in energy-intensive sectors, and lowers carbon emissions. Additionally, when used in heat recovery systems, they reevaluate waste heat, reducing the need for additional energy.

Wide Range of Applications

Their ability to easily adapt to different temperature, pressure, and fluid characteristics allows plate exchangers to be used in a wide variety of industries. They have a wide range of applications, from food and beverage production to power plants, chemical facilities to HVAC systems. Their design, which can be optimized according to the needs of each sector, makes them a universal heat transfer solution.

Safety and System Protection

Plate exchangers eliminate the risk of mixing by preventing the direct contact of two fluids. They also provide protection against sudden pressure changes that may occur in the system, extending the lifespan of the equipment. Especially double-protected plate designs provide maximum safety in sensitive processes.

Design and Engineering Features

The high performance of plate heat exchangers is based on plate geometry, flow arrangement, and material selection designed according to advanced engineering principles. These devices not only provide heat transfer but also optimize fluid dynamics to maximize energy efficiency and system reliability.

Plate Geometry and Surface Design

The plates, the most critical component of plate exchangers, have specially shaped wavy or embossed surfaces. This design allows fluids to move more turbulently over the surface, significantly increasing the heat transfer coefficient. Turbulent flow offers much more efficient heat exchange compared to laminar flow because it increases the time and amount of contact between the fluid and the plate surface.

The surface shapes of the plates are usually designed in "chevron" (herringbone), flat, or wavy forms. Chevron-type plates are preferred in applications requiring high efficiency due to their ability to create high turbulence. This design also reduces sediment and dirt buildup on the plate surface, reducing maintenance frequency.

Flow Arrangement and Hydrodynamic Optimization

In plate exchangers, fluids are usually directed with a counterflow arrangement. This flow type optimizes heat transfer by keeping the temperature difference between hot and cold fluids at maximum. In some special applications, co-current or cross-flow arrangements can also be preferred; thus, the system can be adapted to the temperature profile required by the process.

The channel width between the plates is optimized according to the viscosity and flow rate of the fluid. This allows the fluid's speed and turbulence level to be controlled, minimizes pressure losses, and reduces energy consumption. Additionally, the correct selection of channel geometry eliminates the risk of clogging that fluids containing particles may cause.

Thermal Design and Heat Transfer Performance

The thermal performance of plate exchangers is determined by the correct calculation of surface area, fluid properties, and total heat transfer coefficient. The number of plates and surface area are determined according to the targeted heat load to provide optimum performance. Additionally, the precise adjustment of the inlet and outlet temperatures of hot and cold fluids minimizes energy losses.

This engineering approach allows plate exchangers to perform maximum heat transfer with minimum energy. The ability to provide high efficiency even at low temperature differences offers a significant advantage in terms of energy savings.

Modular and Scalable Structure

The design of plate exchangers is modular. This allows the capacity of the device to be easily increased or decreased according to needs. New plates can be added to expand the heat transfer surface or the number of plates can be reduced to adapt to smaller capacity systems. This feature allows for a quick and economical response to changing process requirements.

Durability and Long-Lasting Use

Plate exchangers are designed to withstand high temperatures and pressures. The sealing systems between the plates and gaskets create a secure barrier against deformations that may arise from thermal expansions. Additionally, thanks to specially selected materials and surface treatments, the devices show high resistance to corrosion and wear. This ensures reliable and uninterrupted performance for many years.

Material Selection and Surface Technologies

The performance, durability, and long-lasting use of plate heat exchangers are directly dependent on the materials used in their production. The correct material selection not only increases heat transfer efficiency but also determines corrosion resistance, mechanical durability, and hygiene standards. The most suitable material selection is made considering the requirements of different industrial applications, ensuring that the exchanger provides reliable performance even under challenging working conditions.

Stainless Steel: High Performance and Economic Solution

Stainless steel is the most commonly used material in plate heat exchangers. Due to its high thermal conductivity, excellent mechanical durability, and corrosion resistance, it is safely preferred in both industrial and commercial applications. Additionally, its relatively low cost, wide application area, and long service life make it an economic solution for businesses. Plates made of stainless steel provide high efficiency in systems operating with hot water, steam, and neutral fluids.

Titanium: Superior Resistance for Challenging Conditions

For systems operating in environments with salty water, seawater, acidic solutions, and high chloride content, titanium plates are preferred. Titanium's exceptional corrosion resistance offers a long-lasting and reliable solution, especially in the maritime, chemical, and energy sectors. This material minimizes the risk of deformation and wear even in systems in contact with aggressive fluids. Additionally, its low density reduces the total weight of plate exchangers, facilitating transportation and installation.

Nickel and Nickel Alloys: Assurance of Chemical Resistance

In some plate exchangers used in the chemical industry and special processes, nickel and nickel alloys are preferred. These materials show excellent resistance, especially in high-temperature and aggressive chemical environments. Nickel alloys maintain their stability in both oxidative and reductive environments, providing high performance in the long term. Additionally, the low thermal expansion coefficient strengthens the seal between the plates and increases system safety.

Duplex Stainless Steel: Balance of High Strength and Corrosion Resistance

In some applications, both high mechanical strength and superior corrosion resistance may be required. In such cases, the use of duplex stainless steel comes to the forefront. Thanks to its microstructure formed by the combination of ferritic and austenitic phases, both mechanical strength is kept at a high level, and superior resistance to chloride-induced corrosion is provided. This material offers long-lasting use in processes under high pressure and temperature.

Surface Treatments and Coating Technologies

Another important factor as important as material selection is surface treatments. Special coatings and treatments applied to the surface of the plates provide additional protection against corrosion and biofilm formation. For example, with passivation processes, a protective oxide layer is formed on the surface, extending the material's lifespan. In some applications, PTFE or special polymer coatings are preferred to increase chemical resistance and facilitate cleaning.

Reducing surface roughness increases both heat transfer efficiency and prevents dirt and sediment buildup. This reduces maintenance frequency and allows the system to operate at high performance for a longer time.

Design Techniques Enhancing Efficiency

One of the most important advantages of plate heat exchangers is that they offer exceptionally high heat transfer efficiency thanks to engineering optimizations made during the design phase. The factors determining the performance of these devices are not only the number of plates or material quality; plate geometry, channel structure, sealing system, and control technologies also directly affect total efficiency. Below, the basic design techniques that enhance this efficiency are explained in detail.

Maximizing Plate Surface Area

Heat transfer capacity is directly proportional to the plate surface area. The specially shaped wavy structure of the plates increases the contact area of the fluid with the surface and creates turbulent flow. This situation significantly increases the heat transfer coefficient. At the same time, the total surface area can be enlarged by increasing the number of plates, and thus the capacity of the exchanger can be easily scaled. This modular structure allows the device's performance to be quickly adapted to different applications.

Optimizing Channel Spacing

The channel width between the plates is carefully determined according to the fluid's properties and system requirements. Narrow channels increase turbulence levels, accelerating heat transfer, while wider channels allow high-viscosity or particle-containing fluids to pass more easily. Selecting the correct channel spacing reduces both pressure losses and energy consumption. This optimization establishes a perfect balance between system efficiency and energy savings.

Advanced Sealing Systems

Sealing between the plates is of critical importance for the safety and efficiency of the exchanger. Advanced gasket designs prevent fluids from leaking into incorrect channels and prevent the mixing of two fluids. This situation increases both process safety and maintains the device's heat transfer performance. Additionally, the easy replaceability of the gasket system shortens maintenance time and reduces downtime.

In some applications, especially in systems operating under high temperature and pressure, semi-welded or fully welded plate designs are preferred. These types of designs maximize sealing safety and provide long-term operational reliability.

Smart Control and Monitoring Systems

In addition to traditional plate exchanger designs, modern systems use smart sensors and automatic control mechanisms. These systems monitor parameters such as fluid temperature, flow rate, and pressure in real-time, maintaining optimal operating conditions. Possible efficiency losses or performance drops are quickly detected and corrected. This approach provides energy savings, especially under variable operating conditions, and extends the exchanger's lifespan.

Improving Flow Arrangement

The counterflow arrangement is the most commonly preferred design in plate exchangers because it optimizes heat transfer by keeping the temperature difference between hot and cold fluids at maximum. However, co-current or cross-flow arrangements can also be used in special applications. These arrangements enhance system performance and optimize energy use based on process requirements.

Reducing Surface Roughness

The surface roughness of the plates is another factor that directly affects heat transfer efficiency. Smooth surfaces allow the fluid to progress more smoothly and controllably over the plates. At the same time, it reduces dirt and sediment buildup, extending maintenance intervals. This allows the system to operate at maximum efficiency for a longer time.

Energy Efficiency and Environmental Sustainability

Plate heat exchangers are not only devices that offer high heat transfer performance; they are also one of the most important components of modern industrial systems in terms of energy efficiency and environmental sustainability. Considering increasing energy costs, strict environmental regulations, and sustainability goals, the advantages provided by these devices hold strategic importance.

Maximum Heat Transfer with Minimum Energy

The basic design of plate exchangers focuses on providing high heat transfer with low energy use. Thanks to the large surface area and turbulent flow, the temperature difference between fluids is effectively utilized, meaning more heat transfer with less energy. Their requirement for much less pumping power compared to traditional systems reduces energy consumption and lowers operating costs.

Additionally, their high efficiency allows them to be produced in smaller sizes. This not only provides energy savings but also contributes to the more efficient operation of other equipment in the system. Lower energy needs directly contribute to reducing carbon emissions and minimizing environmental impacts.

Energy Savings with Waste Heat Recovery

Plate exchangers offer ideal solutions for waste heat recovery, one of the most effective ways to increase energy efficiency. Waste heat released in industrial processes or energy production systems can be reused through exchangers. For example, the heat of a hot fluid coming out of a production line can be used to preheat another fluid. This approach reduces additional energy needs and significantly lowers the total energy consumption of the business.

The reuse of waste heat not only provides energy savings but also increases the overall efficiency of the system and reduces environmental impacts. This allows businesses to more easily achieve sustainable production goals and control energy costs in the long term.

Reducing Carbon Footprint

Another important factor directly related to energy efficiency is the carbon footprint. Lower energy consumption reduces fossil fuel use and contributes to the reduction of greenhouse gas emissions. Plate heat exchangers optimize energy conversion processes, allowing more heat transfer with less fuel. This not only facilitates reaching environmental sustainability goals but also supports businesses' compliance with environmental standards.

Reducing carbon emissions, an important indicator in sustainability reporting, provides not only environmental but also economic advantages for businesses. Low emission values help meet energy efficiency certifications and environmentally friendly production standards.

Compatibility with Renewable Energy Systems

Plate exchangers show excellent compatibility with systems operating with renewable energy sources. Heat energy obtained from sources such as solar energy, geothermal energy, and biomass can be transferred with high efficiency through these devices. Additionally, they are effectively used in energy storage and distribution systems, ensuring more efficient use of energy obtained from renewable sources.

This compatibility reduces dependence on fossil fuels and contributes to the development of more environmentally friendly solutions in energy production. Thus, businesses not only increase current energy efficiency but also serve long-term sustainability strategies.

Circular Economy and Material Sustainability

A large portion of the materials used in plate heat exchangers is recyclable. The reuse of materials such as stainless steel, titanium, and nickel alloys reduces environmental impact and supports the circular economy approach. Additionally, the long-lasting structure of the devices eliminates the need for frequent replacement, reducing resource use and contributing to the sustainable production cycle.

Wide Range of Applications

Plate heat exchangers are used in a very wide range of industrial and commercial applications due to their high efficiency, compact designs, and flexible usage features. Their ability to easily adapt to different temperature, pressure, and fluid characteristics makes them an ideal solution in both heavy industrial conditions and sensitive processes. Below, the main application areas are detailed:

Food Industry

In food production, hygiene, safety, and process control are the top priorities. Plate heat exchangers are widely used in the food sector due to their easy-to-clean structures, high heat transfer efficiency, and production from hygienic materials such as stainless steel. They provide fast and controlled heat exchange in processes such as milk pasteurization, juice cooling, beer, and beverage production without compromising product quality. Additionally, their compatibility with CIP (cleaning in place) systems allows for quick and effective cleaning operations.

Automotive Industry

In the automotive sector, temperature control is of critical importance for production quality and process continuity. Plate exchangers are effectively used in engine test systems, paint and coating lines, and press and mold cooling processes. Their compact designs save space in the production area and can be easily adapted to different process needs with their modular structures. Additionally, they increase production efficiency by providing stable performance even under high temperature and pressure conditions.

Maritime

Maritime applications require reliable operation under challenging environmental conditions such as high salinity and corrosion risk. Plate exchangers made from materials with high corrosion resistance, such as titanium, are safely used in ship cooling systems, freshwater production units, oil cooling circuits, and waste heat recovery lines. Their low maintenance requirement, long service life, and high efficiency make a significant contribution to ensuring operational continuity in the maritime sector.

HVAC Systems

Plate exchangers are widely preferred in building comfort conditioning and hot water supply applications. They work with high efficiency in heating, cooling, ventilation, and domestic water circuits, reducing energy consumption. Their compact designs take up minimal space in machine rooms and offer easy installation and maintenance advantages. Additionally, when used as circuit separators, they increase system safety and prevent different circuits from mixing.

Petrochemical and Pharmaceutical Industry

Equipment used in these sectors must be resistant to high temperature, pressure, and aggressive chemical environments. Plate exchangers offer long-lasting and reliable solutions with material options suitable for these challenging conditions. They provide high heat transfer efficiency in critical processes such as reactor cooling, heating or cooling of process fluids, and solvent recovery. Additionally, they offer safe and stable heat exchange in pharmaceutical production lines requiring precise temperature control.

Metal Industry

Cooling of equipment exposed to high temperature and pressure in metal processing processes is of critical importance. Plate heat exchangers are used in many applications, from rolling mill cooling systems to smelting furnaces. The high efficiency they provide increases process stability in production lines and extends equipment life. Additionally, energy recovery solutions contribute to reducing production costs.

Energy Sector

Plate exchangers are widely used in energy production facilities, cogeneration systems, and heat recovery units. Their high efficiency minimizes losses in energy conversion processes and reduces fuel consumption. Additionally, they increase the total energy efficiency of the system through waste heat recovery. With these features, they make a significant contribution to reducing energy costs and environmental impacts.

Textile Industry

In the textile sector, processes such as printing, dyeing, finishing, and drying are extremely sensitive to temperature control. Plate exchangers ensure production continuity and quality by increasing energy efficiency in these processes. Their ability to quickly change heat shortens production cycles and reduces operating costs. Additionally, their compact structures allow easy integration into existing production lines.

Maintenance, Operation, and Long-Lasting Use

The high efficiency and reliable operation of plate heat exchangers are directly related to regular maintenance and correct operating practices. Although these devices are designed to be long-lasting, factors such as operating conditions, fluid quality, and usage frequency play a decisive role in performance. Correct maintenance strategies extend the system's lifespan, increase energy efficiency, and prevent unexpected downtimes.

Easy to Disassemble and Clean Design

One of the most important advantages of plate exchangers is that cleaning and maintenance operations are quite easy due to their modular and disassemblable designs. Since the plates can be removed one by one, sediment, lime, and dirt layers accumulated on the inner surfaces can be easily cleaned. This feature ensures that the system operates at high performance for a long time and prevents drops in heat transfer efficiency.

Periodic cleaning operations prevent biofilm, corrosion, or chemical deposits that may form on the plate surface. Additionally, during cleaning, gaskets and plate surfaces are thoroughly inspected to detect possible deformations or wear at an early stage.

Periodic Maintenance and Control Processes

Creating a regular maintenance schedule is of critical importance for exchangers to operate efficiently. Maintenance operations performed at intervals determined according to fluid properties and operating conditions maintain the device's long-term performance. During this process, the following checks should be made:

• Check for deformation, cracks, or wear on plate and gasket surfaces.

• Clean if there is sediment, particles, or foreign matter buildup in the plate channels.

• Test gasket flexibility and sealing condition.

• Check for leaks or looseness in inlet-outlet connections.

Regular application of these maintenance steps ensures the early detection of possible malfunctions and prevents high-cost downtimes.

Preventing Leaks and Blockages

One of the most common problems encountered in plate exchangers is leakage or channel blockage. The hardening or deformation of sealing gaskets over time can lead to this problem. Therefore, it is recommended to renew the gaskets at certain periods. Additionally, if the fluid contains particles or foreign matter, channel blockages may occur. To prevent this problem, filtration systems should be used, and fluid quality should be regularly monitored.

The Importance of Fluid Quality

The chemical properties of the fluid used have a significant impact on the lifespan of the plates and gaskets. Especially fluids containing high chloride or aggressive chemicals can increase the risk of corrosion. Therefore, the chemical composition of the fluid should be regularly analyzed, and inhibitors should be used if necessary. Additionally, controlling the pH value in the system extends the lifespan of the plates and gaskets.

Reusability and Environmental Sustainability

Plate heat exchangers can remain in operation for many years thanks to their reusable components. The replaceability of plates and gaskets allows the device's lifespan to be extended without the need for complete renewal. This feature reduces both maintenance costs and offers an advantage in terms of environmental sustainability.

Additionally, their low energy consumption and high efficiency significantly reduce the total cost of ownership in the long term. Plate exchangers, which can provide uninterrupted service for up to 20 years with correct maintenance and operating strategies, stand out as a long-term and sustainable investment.

Conclusion: A Strategic Investment for Efficiency, Reliability, and Sustainability

Plate heat exchangers play a critical role in achieving the efficiency, reliability, and sustainability goals of modern industrial and commercial systems. Thanks to their advanced plate geometry, high heat transfer surface, compact design, and flexible usage features, they provide maximum heat transfer performance while reducing energy consumption. At the same time, with easy maintenance, low operating costs, and long-lasting use advantages, they significantly reduce the total cost of ownership for businesses.

Their wide range of applications has made these devices indispensable not only in heavy industries such as energy, chemistry, or metal but also in different sectors such as food production, HVAC systems, maritime, and automotive. Additionally, their compatibility with renewable energy systems contributes to reducing environmental impacts by providing waste heat recovery and helps reduce the carbon footprint.

In today's world, where increasing energy costs and the need for environmentally friendly production are gaining importance, plate heat exchangers are not just a technical piece of equipment but also a strategic investment tool for businesses. When supported with the right design, appropriate material selection, regular maintenance, and smart control systems, these devices form one of the cornerstones of sustainable production goals by operating at high performance for many years.