Air diaphragm pumps are one of the special types of pumps that ensure the safe, efficient, and economical transfer of liquids and fluids in industrial processes. As the name suggests, the working principle of these pumps is entirely based on compressed air. Unlike traditional centrifugal pumps, they do not require any electric motor. Thanks to this feature, they offer safe usage with their explosion-proof (ex-proof) structures and can be easily operated in environments where access to electricity is difficult.

Diaphragm pumps are actually based on a very old principle: the suction and discharge pump logic. These pumps, which are the modern and industrial versions of pumps operated by human power, use diaphragm and air pressure instead of the piston movement in the pump. With the synchronized movement of two flexible diaphragms, the pump chambers are filled and emptied in turn. Thus, the liquid is transferred from one compartment to another with the help of compressed air and then directed to the discharge line.

The most notable feature of air diaphragm pumps is that they do not use an electric motor. The drive is achieved solely with air. This provides a significant safety advantage, especially in environments with flammable, explosive, or combustible fluids. For this reason, they are among the most preferred pump types in the transfer of fuel, solvent, thinner, paint, and chemical solutions. Since there is no risk of electrical sparks, they create a safe working environment with their ex-proof feature.

Air diaphragm pumps also offer a very versatile working advantage. Their ability to perform deep suction enables fluid transfer even under difficult conditions. They even have the ability to run dry for short periods. Although this feature shortens the life of the diaphragm, it allows the system to continue operating in emergencies. Additionally, the pumping flow rate and pressure can be easily adjusted. By simply changing the air pressure, the pump capacity can be controlled. This makes them an extremely flexible solution according to process requirements.

From an industrial perspective, air diaphragm pumps are widely used not only in liquid transfer but also in circulation, filling, and dosing applications. Their ability to work safely even with acidic, basic, abrasive, or highly viscous fluids is one of the most important advantages that set them apart from other pump types.

In conclusion, air diaphragm pumps are safe, flexible, and durable pumps that operate with compressed air and do not require an electric motor. With their wide range of material options, high chemical resistance, and ease of use, they are indispensable equipment in today's industry.

The working principle of air diaphragm pumps is based on a very simple yet highly effective mechanism. These pumps operate entirely with compressed air instead of an electric motor or mechanical transmission systems. The compressed air coming from the air line connected to the inside of the pump moves the diaphragms located in the pump body back and forth in sequence. This movement enables the suction and discharge processes to occur.

There are usually two diaphragms in the pump body, and these diaphragms are connected to each other via a shaft. When compressed air acts on one diaphragm, this diaphragm moves outward while the other diaphragm moves in the opposite direction. Thus, while one chamber fills, the other chamber empties. This synchronized movement allows the pump to continuously suck and discharge the liquid.

During operation, the liquid never comes into direct contact with the air. While the liquid moves in the chambers located on the liquid side of the pump, the air is only present on the back surface of the diaphragm. This makes it possible to safely transfer especially flammable or sensitive fluids. Additionally, thanks to the self-priming structure of diaphragm pumps, there is no need for pre-filling the system to start the pump.

Another important feature of air diaphragm pumps is the ease of adjusting flow capacity and pressure. When the air pressure at which the pump is operated is changed, the flow rate of the pump changes at the same rate. This flexibility makes them ideal equipment that can adapt to different process needs. Additionally, air diaphragm pumps can be operated at infinitely variable speeds if desired; this provides a great advantage especially in sensitive applications such as dosing.

Another standout point among the basic features is their ability to run dry. While most pump types are damaged in a short time when running dry, air diaphragm pumps are resistant to short-term dry running. This feature increases the safety of the system in cases where fluid flow is suddenly interrupted or the tank is emptied.

Moreover, these pumps can work with a wide range of fluids, from high-viscosity liquids to abrasive chemicals. Their ability to operate without clogging even with fluids containing solid particles makes them very versatile in the industry. Thanks to their durable body structure, chemical-compatible material alternatives (PP, PVDF, aluminum, stainless steel, etc.), and long-lasting diaphragm technologies, air diaphragm pumps can be used safely even under the most challenging conditions.

In conclusion, the working principle of air diaphragm pumps is based on compressed air, flexible diaphragms, and synchronized chamber movement. This simple yet effective structure makes the pumps safe, economical, durable, and highly versatile.

Advantages of Air Diaphragm Pumps

Air diaphragm pumps have a very wide range of uses in the industry thanks to their unique working mechanism and durable structures. Working with compressed air instead of an electric motor sets them apart from other pump types in many ways. Here are the prominent advantages of these pumps:

1. Ex-proof safety

One of the most important advantages of air diaphragm pumps is that they do not create a spark risk as they do not use an electric motor. This feature provides a safe working opportunity in environments with a risk of explosion, such as fuel, solvent, paint, chemical solution, and flammable gases. Thanks to their ex-proof feature, they are the most preferred pump type in sensitive industries such as refineries, chemical plants, and paint production lines.

2. Ability to run dry

Many pump types are not suitable for dry running and can be damaged in a short time when there is no fluid. Air diaphragm pumps stand out with their ability to run dry for certain periods. This feature especially protects the system in cases where tanks are emptied or flow is interrupted.

3. Self-priming feature

These pumps can operate as self-priming without the need for any pre-filling. Thanks to their ability to perform deep suction, they show safe performance even in applications where the fluid level is low.

4. Wide range of fluids

Air diaphragm pumps can be used in a wide range from low-viscosity liquids to high-viscosity and even fluids containing solid particles. They provide long-lasting use with the correct material selection in chemicals with acidic, basic, or abrasive properties.

5. Easy flow and pressure control

By adjusting the air pressure at which the pump operates, flow and pressure can be easily controlled. This feature provides a great advantage, especially in processes with sensitive dosing or different flow needs.

6. Compact and portable structure

Unlike large-area solutions like fan and electric systems, air diaphragm pumps can be mounted in narrow spaces thanks to their compact structures. Their lightweight and ergonomic designs make them easily portable and usable in mobile applications.

7. Low maintenance requirement

Diaphragm pumps have very few moving parts due to their simple mechanical structure. This situation minimizes the maintenance needs of the pumps. Additionally, the ease of replacing diaphragms and valves speeds up the maintenance process and reduces operating costs.

8. Long-lasting use

When produced with the correct material selection (e.g., stainless steel, aluminum, PP, PVDF), air diaphragm pumps can work reliably for many years. Thanks to high chemical resistance diaphragm technologies, they maintain their performance even under difficult conditions.

9. Energy efficiency

Advanced air valve designs ensure that the pumps use air most efficiently. Thus, while energy consumption is reduced, pumping performance is kept high. This significantly reduces operating costs, especially in continuously operating systems.

10. Versatile use

Air diaphragm pumps can be used not only for transfer but also for filling, dosing, circulation, and mixing in many different applications. Their wide range of uses makes them one of the most flexible solutions in the industry.

In conclusion, air diaphragm pumps have become indispensable in the industry with the advantages they offer in terms of safety, durability, efficiency, and ease of use. Whether it is solvent transfer in a chemical plant, syrup filling in the food sector, or waste liquid transfer in a power plant, air diaphragm pumps provide reliable performance under all conditions.

Usage Areas and Industrial Applications

Air diaphragm pumps can be used in almost all areas of the industry thanks to their safe working principle, wide range of material options, and versatile structures. Their operation with compressed air, not requiring an electric motor, and ex-proof (explosion-proof) features make them indispensable, especially in risky environments. Here are the prominent usage areas of air diaphragm pumps:

1. Chemical and Petrochemical Industry

Safety and durability are the most critical factors in chemical processes. Air diaphragm pumps ensure the safe transfer of fluids with acidic, basic, solvent-based, or abrasive properties. Since no electric motor is used, the risk of explosion is eliminated, and potential dangers from chemical reactions are minimized. They can also be used safely in pumping high-viscosity or particle-containing liquids.

2. Transfer of Fuel and Flammable Liquids

Flammable liquids such as gasoline, diesel, kerosene, thinner, and solvent pose serious risks in pumps operating with electricity. Air diaphragm pumps ensure the safe transfer of such fluids thanks to their ex-proof features. Refineries, fuel depots, filling facilities, and paint factories are some of the areas where these pumps are most intensively used.

3. Food and Beverage Industry

They are widely preferred in the food sector thanks to their hygienic designs. They can be used in the transfer of food products such as milk, cream, yogurt, syrup, molasses, honey, fruit juice, beer, and wine. Food-grade models made of stainless steel comply with FDA and European food standards. They do not alter the structure of the products, preserve their nutritional value, and ensure hygienic transfer.

4. Pharmaceutical and Cosmetic Industry

Fluids used in pharmaceutical production and the cosmetic sector are often both valuable and sensitive. Diaphragm pumps do not alter the structure of the products as they operate with low shear force. They can be used safely in the transfer of products such as cream, lotion, shampoo, syrup, and chemical solutions. Additionally, their production in compliance with GMP (Good Manufacturing Practice) standards makes them easily preferred in these sectors.

5. Paint and Coating Industry

Paint, varnish, coating liquids, and solvents are products that are difficult to pump due to their high viscosity. Air diaphragm pumps can easily transfer high-viscosity fluids. Additionally, they provide safe operation with their explosion-proof feature in solvent-based products. They are frequently used in paint lines in the automotive industry, metal coating facilities, and furniture production.

6. Wastewater and Sludge Transfer

Air diaphragm pumps can easily pump fluids containing solid particles. Therefore, they are widely used in the transfer of sludge, particulate fluids, and chemical wastes in wastewater treatment plants. Thanks to their self-priming feature, they have a low risk of clogging and require minimal maintenance.

7. Mining and Construction Sector

They offer ideal solutions in the discharge of underground waters and the transfer of muddy and particulate fluids. They are also used for oil, water, and chemical transfer in tunnel boring machines, drilling, and breaking machines. In the construction sector, they are preferred for the transfer of concrete additives, chemical additives, and mortar.

8. Agriculture and Agricultural Applications

Air diaphragm pumps offer safe and efficient solutions in the transfer of oil, fertilizers, and agricultural chemicals used in agricultural machinery. They can also be used in the mixing and distribution of chemical additives in irrigation systems.

9. Energy and Power Plants

They are used in energy production facilities, especially in the transfer of various chemical additives and process fluids used in biomass and geothermal plants. Thanks to their durable structures, they are resistant to high temperatures and pressures.

10. Maritime and Aviation

They are widely preferred in the transfer of fuel, oil, and ballast waters in maritime; and in the safe pumping of fuel and chemical fluids in aviation. Their ex-proof features meet the safety requirements in these sectors.

In conclusion, air diaphragm pumps are used in a very wide range from chemicals, food, pharmaceuticals, paint, mining, agriculture, energy, and maritime. Thanks to their versatility, safety features, and durable structures, they have become one of the most critical equipment in industrial facilities.

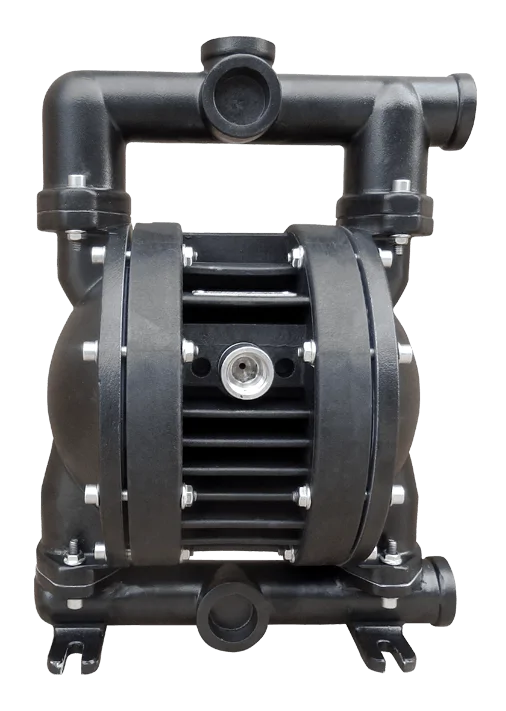

Ruby Air Diaphragm Pumps: Powerful and Innovative Solutions

Reliability, efficiency, and long-lasting performance in industrial fluid transfer are among the most important expectations of every business. At this point, Ruby air diaphragm pumps are one of the standout solutions with their high performance and innovative design features. Not only do they incorporate all the advantages of traditional diaphragm pumps, but they also stand out with special design details that enhance user experience and energy efficiency.

One of the most notable advantages of Ruby pumps is the improved diaphragm technology. Thanks to the new generation composite diaphragm structure, greater displacement per cycle is achieved. This means less energy consumption to reach the same flow rate. The design without a central hole in the diaphragm eliminates potential leakage risks, providing long-lasting operation and low maintenance needs. This feature offers a significant advantage for businesses in terms of both safety and operational costs.

Ruby air diaphragm pumps are optimized to provide economical air consumption. The innovative air valve design allows for more efficient use of compressed air. This minimizes energy consumption while maintaining the overall performance of the pump at a high level. Especially in industrial facilities operating 24/7, energy efficiency directly reduces operating expenses, providing significant savings.

In terms of durability, Ruby pumps stand out. Thanks to the offering of different material alternatives (PP, PVDF, aluminum, AISI 316 stainless steel) in the body and hydraulic parts, the pump can be adapted to different chemical environments. They provide safe and long-lasting performance in the transfer of challenging substances such as aggressive acids, solvents, paint, and flammable fluids. Additionally, their conductive series provide ex-proof safety in environments with high explosion potential.

The user-friendly features of Ruby pumps are also noteworthy. Easy disassembly and assembly capabilities shorten maintenance times, minimizing production losses. Thanks to their modular structure, the inlet and outlet directions can be easily changed, allowing for quick adaptation to different installation conditions. Additionally, the embedded piston diaphragms offer the advantage of quiet and balanced operation.

Another important innovation is the possibility of submersible use. Ruby air diaphragm pumps can safely operate even in dirty, dusty, and high particulate environments thanks to their closed designs. They can also be used by being directly placed into liquids as a submersible type. This flexibility significantly expands the usage areas of the pumps.

In conclusion, Ruby air diaphragm pumps offer an economical and reliable solution for industrial facilities with their advanced diaphragm technology, low energy consumption, long-lasting use, and user-friendly designs. Thanks to different models suitable for the needs of the sector, they enhance the efficiency of businesses by demonstrating superior performance in all kinds of applications from transfer to filling, circulation to dosing.

Technical Features of Ruby Air Diaphragm Pumps

Ruby air diaphragm pumps are a solution that stands out in the industry not only with their powerful performance but also with their technical features. Developed to meet the needs of different sectors, these pumps offer many advantages in terms of durability, safety, energy efficiency, and flexible use.

Material Variety

Ruby pumps are produced with a wide range of material options to adapt to different fluid types. PP (polypropylene) and PVDF (polyvinylidene fluoride) bodies are preferred in applications with high chemical resistance, while aluminum and AISI 316 stainless steel options stand out in challenging processes requiring mechanical strength and long-lasting use. This variety allows the pumps to cater to a wide range of applications from the food industry to the chemical industry.

Explosion-proof (Ex-proof) Feature

Since they do not operate with an electric motor, Ruby air diaphragm pumps do not produce sparks. This feature provides ex-proof safety, especially in environments with solvents, fuel, paint, thinner, and similar flammable fluids. Models with conductive bodies prevent the accumulation of static electricity, completely eliminating the risk of explosion.

Energy Efficiency and Air Consumption

The advanced air valve design used in Ruby pumps minimizes air consumption while keeping performance at a high level. Economic air consumption reduces the operating costs of the pumps and provides significant energy savings in long-term use.

Oil-free Operation and Ecological Design

Ruby pumps can operate without oil. This feature offers an environmentally friendly design while also reducing maintenance needs. Their ecological designs minimize environmental impacts, contributing to sustainable production policies.

Advanced Diaphragm Technology

New generation composite PTFE diaphragms are designed for long-lasting use. The design without a central hole eliminates potential leakage points. The larger surface area of the diaphragm allows for more displacement per cycle, thereby increasing pump performance.

Easy Assembly and Maintenance

Ruby pumps stand out with their user-friendly structures. Easily disassembled and reassembled parts shorten maintenance times, minimizing production interruptions. Additionally, the ability to change the inlet and outlet directions allows for quick adaptation to different system installations.

Submersible Use Capability

Thanks to their closed design, Ruby air diaphragm pumps can also be used as submersible. This feature allows the pumps to be placed directly into the liquid. They can continue to operate safely even in dirty, dusty, or high particulate environments.

Temperature and Pressure Resistance

Ruby pumps can operate safely under different temperature and pressure conditions depending on the material used. Models selected according to chemical compatibility tables provide long-lasting performance even in the transfer of viscous fluids or aggressive chemicals at high temperatures.

In conclusion, Ruby air diaphragm pumps are one of the most reliable and efficient solutions in the industry with their material variety, ex-proof safety, low energy consumption, advanced diaphragm technology, and ease of maintenance. These features make them not just a pump, but also a strategic investment tool for businesses.

Benefits Provided by Ruby Air Diaphragm Pumps

Ruby air diaphragm pumps are among the most reliable solutions in the industry not only with their technical features but also with the versatile benefits they provide. Their advanced designs, energy efficiency, ease of use, and durable structures offer significant advantages to businesses both economically and operationally.

1. Safety and Ex-Proof Working Opportunity

One of the biggest benefits of Ruby pumps is that they operate solely with compressed air without the need for an electric motor. Thanks to this feature, the pumps can be safely used in explosive and flammable environments without the risk of sparks. They provide maximum safety to businesses, especially in the transfer of high-risk fluids such as solvents, fuel, thinner, and paint.

2. Energy Savings and Low Operating Costs

Ruby air diaphragm pumps highlight energy efficiency with their innovative air valve design that provides economical air consumption. Offering higher performance with less air significantly reduces operating costs. Additionally, the low maintenance requirement creates a cost advantage in the long term.

3. Long-lasting and Durable Use

Thanks to durable material options such as stainless steel, aluminum, PP, or PVDF, the pumps can work safely for many years even under the most challenging conditions. Their resistance to high temperatures, pressure, and abrasive chemicals extends the system life, accelerating the return on investment.

4. Flexible and Versatile Use

Ruby pumps can transfer fluids of different viscosities without any problems. Thus, they have a wide range of uses from food products to chemical solutions, high-viscosity paint and sludge to solvent-based fluids. Additionally, the possibility of submersible use allows the pumps to offer much more flexible solutions.

5. Easy Installation and Maintenance

Thanks to their modular structures, Ruby pumps have a user-friendly design. Easily removable and replaceable parts minimize maintenance times and reduce production losses. Additionally, the ability to change the inlet and outlet directions makes it easy for the pumps to adapt to different installation scenarios.

6. Protecting Product Quality

Ruby air diaphragm pumps do not alter the structure of sensitive products as they operate with low shear force. Protecting the physical or chemical structures of products is of critical importance, especially in the food, pharmaceutical, and cosmetic sectors. These pumps ensure product quality, contributing to businesses producing in compliance with standards.

7. Environmentally Friendly and Sustainable Solution

Thanks to their oil-free operation feature and ecological design, Ruby pumps minimize environmental impacts. Being made of 100% recyclable materials shows that they offer an environmentally friendly solution. Additionally, their low energy consumption contributes to reducing the carbon footprint of businesses.

8. High Performance and Efficiency

The new generation composite PTFE diaphragm technology increases the efficiency of the pump by providing more displacement per cycle. This feature saves both time and energy, especially in facilities with intensive production.

In conclusion, Ruby air diaphragm pumps offer many benefits from safety to energy efficiency, flexibility to protecting product quality. Thanks to these features, they become not just a pump but a strategic investment that enhances the sustainability and competitiveness of businesses.

Conclusion: Reliable and Efficient Solutions with Ruby Air Diaphragm Pumps

In today's industry, fluid transfer is not only an operational need but also a strategic element in terms of safety, efficiency, and sustainability. Air diaphragm pumps play a critical role in the industry, especially with their structures that do not require an electric motor, ex-proof safety features, and wide usage areas. In this context, Ruby air diaphragm pumps are one of the standout solutions with their innovative design, energy efficiency, and long-lasting performance.

The improved diaphragm technology of Ruby pumps combines high pumping capacity with low energy consumption by providing more displacement per cycle. This feature provides businesses with both production continuity and cost advantage. At the same time, the easy maintenance opportunity and modular design minimize production interruptions, offering quick installation and practical use.

Thanks to durable material options (PP, PVDF, aluminum, AISI 316 stainless steel), Ruby pumps can be used safely in many different sectors from chemical plants to food production lines, energy plants to the pharmaceutical industry. With ex-proof safety in environments with explosion potential and long-lasting performance under high temperature and pressure, these pumps are the reliable solution partner of businesses.

One of the biggest advantages provided by Ruby air diaphragm pumps is their versatility. Their ability to be used in different processes such as transfer, filling, dosing, or circulation makes them not just a pump but a strategic equipment at the heart of industrial processes. Additionally, their environmentally friendly designs and low energy consumption contribute to the sustainability goals, which is one of the most important elements of modern production understanding.

In conclusion, Ruby air diaphragm pumps provide businesses with reliability, durability, energy efficiency, and cost advantage, offering a solution suitable not only for today's needs but also for the future. The Ruby series, produced with the engineering expertise and quality assurance of Ekin Industrial, makes a difference in the industry with its high-performance and long-lasting structure. If you are looking for a safe, efficient, and sustainable fluid transfer solution in your facility, Ruby air diaphragm pumps are the best choice.