What is an Air Diaphragm Pump?

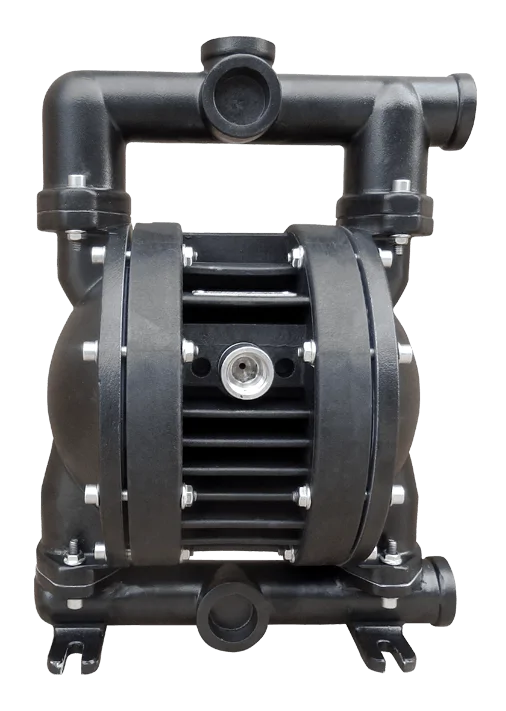

Air diaphragm pumps are types of positive displacement pumps that provide high reliability, flexibility, and safety in the transfer of liquids and viscous fluids. These pumps are preferred in environments with explosion risks because they operate using compressed air instead of electrical energy. The basic principle involves the transfer of liquid from one chamber to another through the back-and-forth movement of two flexible diaphragms. This allows for simultaneous suction and discharge, ensuring a continuous flow.

The movement of the diaphragms is controlled by an air valve located at the center of the pump. This system directs the air pressure alternately between the diaphragms, allowing the liquid to be sucked in and discharged. The absence of an electric motor makes air diaphragm pumps an ex-proof (explosion-proof) solution. This feature creates a significant safety advantage in industries working with flammable and explosive fluids.

Additionally, these pumps are resistant to dry running, easily portable, and the flow and pressure values can be precisely controlled by adjusting the air pressure. They are widely used in many industries such as food, chemicals, automotive, energy, textiles, and more due to their stable performance even with high-viscosity liquids. With long-lasting components and low maintenance needs, air diaphragm pumps are one of the indispensable pieces of equipment in modern industrial processes.

Air Diaphragm Pumps in the Food Industry

The food industry is one of the sectors where hygiene, quality, and production safety must be maintained at the highest level. It is not enough for the equipment used in this field to perform well; all components in contact with food must also be suitable for human health, easy to clean, and durable. Air diaphragm pumps are ideal equipment that meets these requirements.

Air diaphragm pumps made from hygienic materials such as stainless steel, PP, or PVDF prevent liquid accumulation and do not allow bacterial growth due to their smooth inner surfaces. This feature provides a significant advantage in sensitive processes such as the production of dairy products, fruit juices, syrups, chocolate, sauces, creams, or beverages. They do not alter the structure of the fluid during product transfer and prevent quality losses that may arise from temperature or pressure changes. Thus, the texture, aroma, and quality of the final product are preserved.

Moreover, air diaphragm pumps provide high flexibility in production processes thanks to the easy adjustment of pumping speed and pressure. This feature allows food products with different viscosities (such as thick syrups or liquid beverages) to be processed in the same system. They are also quite economical in terms of energy consumption; optimized designs ensure low operating costs.

Ease of maintenance is also one of the most significant advantages of air diaphragm pumps in the food industry. Their structure allows them to be disassembled and cleaned without tools, speeding up cleaning and maintenance processes. This minimizes downtime in production lines and increases production efficiency.

Additionally, the long lifespan of the diaphragm structure reduces the need for frequent maintenance or spare parts, lowering operating costs.

All these features make air diaphragm pumps compliant with food safety standards (such as EHEDG or FDA compliance). With a hygienic production environment, safe operating principles, energy efficiency, and low maintenance requirements, air diaphragm pumps are indispensable components in modern food facilities for processes such as dairy products, beverages, sauces, and flavor production.

Ruby air diaphragm pumps stand out in this field with their advanced design and high performance. Their easy assembly, low air consumption, long-lasting composite diaphragm structure, and quiet operation perfectly balance efficiency and hygiene at every stage of the food industry.

Air Diaphragm Pumps in the Automotive Sector

The automotive sector is an industry that requires high precision, continuous performance, and long life in its production processes. Equipment used at every stage, from assembly lines to paint booths, testing systems to maintenance workshops, must be reliable, durable, and controllable. At this point, air diaphragm pumps offer safe and high-performance solutions suitable for the challenging conditions of the automotive industry.

Air diaphragm pumps that operate with compressed air do not create sparks since no electric motor is used, and they stand out with their explosion-proof (ex-proof) features. They operate safely in environments containing paint, solvents, thinners, and chemical mixtures, completely eliminating the risk of fire or explosion. This feature provides maximum safety in paint lines, coating systems, and chemical transfer areas.

Additionally, air diaphragm pumps are extremely effective in transferring high-viscosity liquids. They can smoothly transfer dense fluids such as motor oil, grease, antifreeze, adhesives, or coating chemicals. For this reason, they are frequently preferred in both production and maintenance areas. The ability to adjust the pumping flow through air pressure makes it easier to control the liquid flow rate in automotive production lines. Thus, the desired precision and stability are achieved in every process.

Thanks to their compact body structures, these pumps can be easily mounted in tight spaces and accelerate maintenance and cleaning processes with their modular designs. The tool-free assembly system minimizes downtime in production lines. Additionally, the long lifespan of the diaphragm structure reduces maintenance costs and increases equipment continuity.

Quiet, vibration-free, and oil-free operation features enhance comfort in the production environment while reducing environmental impacts. The oil-free operation principle prevents harmful waste from being generated, allowing businesses to comply more easily with sustainable production standards. This feature is also a significant advantage in terms of environmentally friendly production policies, which are becoming increasingly important in the automotive sector.

Air diaphragm pumps are widely used in the automotive sector not only for liquid transfer but also in testing systems, fuel and oil filling lines, surface cleaning, and maintenance processes. Their high pressure resistance, variable flow control, and ability to operate dry make these pumps a versatile solution.

Ruby air diaphragm pumps offer models specifically designed for the demands of the automotive industry. The new generation air valve system provides high efficiency with low air consumption and optimized diaphragm geometry. Thanks to durable material alternatives (aluminum, stainless steel, PP, PVDF), it offers maximum protection against chemicals and solvents.

As a result, air diaphragm pumps are modern pumping solutions that enhance production quality in the automotive industry, support energy efficiency, and elevate safety standards. With the flexibility, durability, and control advantages they provide in both production lines and maintenance processes, they make a strong contribution to the automotive sector's vision of sustainable production.

Air Diaphragm Pumps in Marine Applications

The maritime sector requires equipment with high durability due to the harshness of environmental conditions and the continuity of operations. Factors such as corrosion caused by saltwater, vibration, high humidity, and limited space create a need for special material quality and reliability in the pump systems used. Air diaphragm pumps stand out as durable, safe, and long-lasting solutions that meet these requirements.

Operating with fully pressurized air eliminates electrical hazards commonly encountered in marine environments. Since there is no electric motor, there is no risk of short circuits, sparks, or explosions. This feature provides significant safety advantages, especially in areas where fuel, oil, solvent, or chemical transfers occur. In this regard, air diaphragm pumps have become a reliable choice in ship machinery, bilge systems, ballast water transfer, and wastewater management.

They are produced with material alternatives that are structurally resistant to saltwater and chemical corrosion. Body options such as AISI 316 stainless steel or PVDF prevent deformation and rust even in long-term marine environments. Additionally, their compact and lightweight designs facilitate easy installation in confined spaces such as ship holds or engine rooms. This feature offers significant advantages in both new system installations and the modernization of existing systems.

The ability of air diaphragm pumps to operate dry and pump fluids with variable viscosity without strain is critical for the operational variability encountered in maritime applications. All fluids with different densities and compositions, such as bilge water, oil, fuel, chemical mixtures, or waste liquids, can be safely transferred with the same system. Furthermore, their capability to be used in submersible types provides a practical solution, especially in challenging drainage operations or flood-prone areas.

Air diaphragm pumps increase onboard comfort due to their quiet and vibration-free operation. This feature is important for reducing equipment noise during long voyages and providing a comfortable working environment. Modern models with low air consumption reduce ship operating costs by saving energy.

In terms of maintenance processes, they are also quite suitable for marine applications. The tool-free disassembly system allows for quick intervention in case of failures or during periodic maintenance. The long-lasting structure of diaphragm and valve components reduces maintenance frequency and ensures the uninterrupted continuation of ship operations.

Ruby air diaphragm pumps have been developed to meet these requirements in marine applications. Advanced composite diaphragm technology, low ice barrier levels, and next-generation air valve design provide high efficiency even in challenging marine conditions. Their compact design, quiet operation, and durable body structure offer a long-lasting, safe, and sustainable solution for tasks such as fuel, bilge, wastewater, and chemical transfer.

Air Diaphragm Pumps in HVAC Systems

HVAC (Heating, Ventilation, and Air Conditioning) systems are one of the most critical infrastructures for comfort and energy management in modern buildings. The equipment used in these systems is not only responsible for fluid transfer but also for increasing energy efficiency, maintaining system balance, and providing long-lasting, trouble-free operational performance. Air diaphragm pumps hold an important place among durable and economical solutions that respond to these needs.

Since these pumps operate with fully pressurized air, they do not require electrical energy. This feature ensures safe use, especially in technical areas with high humidity or explosion risks. The absence of an electric motor eliminates the risk of sparks or short circuits in the environments where HVAC systems operate. Thus, both energy savings are achieved, and the level of safety is elevated.

The pumping flow rate and pressure of air diaphragm pumps can be easily adjusted through air pressure. This feature helps maintain process balance, which is one of the most important elements of HVAC systems. For example, optimizing flow rates in cooling towers, heat recovery systems, or chiller lines directly affects the overall efficiency of the system. Diaphragm pumps offer precise control to maintain this balance.

Additionally, their structures resistant to dry operation prevent damage to the pumps when the liquid flow is interrupted or when air is present. This feature reduces downtime in facilities and supports operational continuity. Thanks to their compact body design, they can be easily installed in tight spaces, and their quiet operation minimizes noise levels, especially in indoor building applications.

Air diaphragm pumps provide high chemical resistance in the transfer of antifreeze, glycol mixtures, condensate, or chemical additives commonly used in HVAC applications. Material alternatives such as stainless steel, PP, or PVDF ensure long-lasting performance and sealing. Moreover, their oil-free operating principles offer an environmentally friendly system structure with low maintenance requirements.

Energy efficiency is one of the most important criteria in today's building technologies. Air diaphragm pumps stand out in this area due to their low air consumption and high pressure efficiency. Thanks to their convertible flow capacity, systems consume only the energy needed. This results in significant savings in operating costs.

The Ruby series air diaphragm pumps stand out with their models specifically optimized for HVAC applications. The next-generation air valve structure provides high stability in heating and cooling circuits with a low ice barrier level and long-lasting PTFE diaphragm technology. Thanks to their easily disassemblable structure, maintenance operations are completed in a short time, and the system continues to operate without interruption.

Air Diaphragm Pumps in the Petrochemical and Pharmaceutical Industry

The petrochemical and pharmaceutical industries attract attention with production environments that require high precision, safety, and chemical resistance. Pumps used in these areas must be compatible with aggressive fluids and operate safely in environments with explosion risks. Air diaphragm pumps are one of the ideal solutions that meet these needs.

Working with compressed air instead of electrical energy makes these pumps ex-proof (explosion-proof). This feature ensures safe use in facilities containing solvents, acids, bases, fuels, resins, and similar chemicals. Additionally, models with conductive bodies eliminate the risk of static electricity accumulation, thereby removing the explosion risk.

Air diaphragm pumps can transfer high-viscosity or corrosive liquids without structural degradation. This feature ensures the safe transport of sterile formulations or sensitive components in the pharmaceutical industry. Moreover, since the surfaces of the pump that come into contact with the liquid are made from chemically resistant materials such as stainless steel, PVDF, or PTFE, they offer a long-lasting and leak-proof structure.

Their easy disassembly and cleaning accelerate sterilization processes in pharmaceutical production. Low maintenance requirements and keeping energy consumption at an economical level provide both operational and environmental efficiency. With all these advantages, air diaphragm pumps are among the preferred solutions for safe, efficient, and sustainable fluid transfer in the petrochemical and pharmaceutical industries.

Air Diaphragm Pumps in the Metal Industry

The metal industry is a challenging field characterized by high temperatures, abrasive chemicals, particulate fluids, and intense production pace. Therefore, the durability, chemical resistance, and continuous operational performance of all equipment used are of great importance. Air diaphragm pumps have become an indispensable solution in metal processing processes with their robust structures and safe operating principles that meet these requirements.

Air diaphragm pumps are safely used in numerous applications such as coating, surface cleaning, acidification, washing, cooling fluid circulation, and the transfer of metal processing chemicals. Their operation entirely with compressed air, without the need for electrical energy, eliminates the risk of explosion or short circuits in environments where solvent and chemical vapors are present. This feature provides a high safety standard, especially in chemical surface preparation and electroplating lines.

These pumps have the ability to transfer high-viscosity, particulate, or abrasive fluids without difficulty. The transportation of chemicals used in acid, alkaline, solvent, or metal plating baths during metal processing can be challenging for most pumps. However, air diaphragm pumps demonstrate high performance even in such aggressive fluids thanks to their diaphragm structure and wide tolerances in liquid passage channels.

The materials used for the body – aluminum, AISI 316 stainless steel, or PVDF – provide high chemical resistance and long life. These materials prevent corrosion in abrasive environments and extend the maintenance intervals of the pump. As a result, unplanned downtimes in production lines are reduced, and operational efficiency increases. Additionally, the leak-proof design supports workplace safety by eliminating the risk of chemical leaks.

The ability to easily adjust pumping speed and pressure with air pressure allows for precise control of processes. This feature is extremely important in production lines that require maintaining coating thickness, chemical dosage, or liquid flow rates within specific limits. Precise flow control reduces material waste, saves energy, and standardizes production quality.

Air diaphragm pumps are also suitable for production areas where noise levels need to be kept low due to their vibration-free and quiet operation. The oil-free operating principle does not harm the environment and facilitates maintenance operations. Since diaphragm replacement and internal cleaning can be done without tools, maintenance times are quite short.

The Ruby series air diaphragm pumps have been developed to offer high performance and reliability in metal industry applications. Advanced composite diaphragm technology, optimized air valve systems, and low air consumption provide long-lasting, efficient use. Additionally, their superior resistance to abrasive chemicals offers long-term stability in surface processing lines, chemical coating facilities, and galvanizing production.

In conclusion, air diaphragm pumps stand out not only as a transfer equipment in the metal industry but also as a strategic component that directly affects production efficiency, safety, and quality control. With their robust structure, low maintenance needs, and high durability, they provide a safe, sustainable, and economical solution in the metal processing industry.

Air Diaphragm Pumps in Energy Production

The energy sector is one of the industries where continuity and high efficiency are paramount. It is crucial that all equipment used in this field is reliable, durable, and requires low maintenance. Air diaphragm pumps provide reliable solutions that respond to these needs in energy production, cogeneration, and heat recovery systems.

By operating entirely with compressed air without using electricity, they ensure safe use in environments with high temperatures and flammable gases. Additionally, they exhibit long-lasting performance with high chemical resistance material structures in the transfer of chemical additives, cooling fluids, or wastewater commonly encountered in power plants.

The ability to easily adjust the pumping flow rate with air pressure refines process control and ensures stable flow in energy systems. This situation particularly helps to increase thermal efficiency in heat recovery systems. Furthermore, the ability of air diaphragm pumps to operate dry prevents damage to the equipment in situations such as downtime or liquid cutoff.

Quiet operation, low maintenance requirements, and compact design lead to shorter maintenance times and increased operational efficiency in energy production facilities. Air diaphragm pumps stand out as eco-friendly and safe pump solutions that support sustainability goals in the energy sector.

Air Diaphragm Pumps in the Textile Industry

The textile industry is a production area where processes require continuous flow and have high chemical and temperature sensitivity. Therefore, pumps must be both chemically resistant and suitable for long-term operation. Air diaphragm pumps are durable and efficient systems that fully meet these requirements in textile facilities.

Different fluids with varying densities and temperatures are used in production stages such as dyeing, printing, finishing, washing, and drying. Air diaphragm pumps ensure the seamless transfer of these liquids regardless of viscosity differences. Additionally, since they do not alter the structure of the fluid during the pumping process, they maintain the homogeneity of dye and chemical mixtures.

Working with compressed air eliminates the safety risks that electric systems may pose. This feature provides a safe working environment, especially in dye workshops where solvents or flammable chemicals are used. Furthermore, the flow and pressure settings of the pumps can be easily adjusted, providing great flexibility in process control.

Advantages such as easy maintenance, long-lasting diaphragm structure, and compact design support production continuity in textile facilities. Their energy-saving structures reduce operating costs. With all these features, air diaphragm pumps are reliable pump solutions that enhance both production quality and operational efficiency in the textile industry.

Conclusion: Safe, Durable, and Efficient Solutions in Industrial Applications

Air diaphragm pumps are among the pump systems that stand out in terms of reliability, efficiency, and flexibility in today's industrial production processes. Their operation with compressed air means they do not require electrical energy, which translates to both energy savings and a high safety standard. Particularly in applications where the use of electrical equipment is dangerous due to explosion risks or humid environments, air diaphragm pumps offer a safe alternative for businesses.

Their ability to transfer high-viscosity, abrasive, or chemically aggressive fluids seamlessly makes these pumps indispensable in a wide variety of industries. They can be used in a broad spectrum from food production to automotive painting lines, from marine systems to energy plants. They also provide long-lasting use, ease of maintenance, and operational efficiency in sectors such as HVAC, textiles, metal processing, and petrochemicals.

Another prominent advantage of air diaphragm pumps is that the pumping flow rate and pressure can be easily adjusted through air pressure. This feature provides precise flow control in production processes and maintains the balance of the process. Additionally, their durable structure against dry running prevents equipment damage in cases of liquid cut-off. Thus, both production continuity is ensured, and maintenance costs are minimized.

The Ruby series air diaphragm pumps are among the most advanced examples of this technology. Their innovative air valve structure, advanced composite diaphragm technology, and low air consumption increase energy efficiency without compromising performance. Thanks to their user-friendly design, assembly, maintenance, and cleaning processes are quite easy.

In conclusion, air diaphragm pumps are not just equipment that provides fluid transfer; they are a strategic solution that enhances industrial efficiency. With their safe operating principle, durable structure, and wide range of applications, they offer businesses a sustainable advantage in the long term. Ruby air diaphragm pumps set the modern standards in this field, enabling various sectors to achieve safe, economical, and environmentally friendly production goals.