Heat exchangers are equipment that increase energy efficiency by transferring heat between fluids at different temperatures and are one of the fundamental components of industrial processes. However, not all heat exchangers are the same; different design and structural options come to the fore depending on the type of application, operating conditions, and process requirements. At this point, plate (gasketed) and brazed heat exchangers, which are the two most common solutions, work on a similar basic principle but differ significantly in terms of design, usage area, and performance.

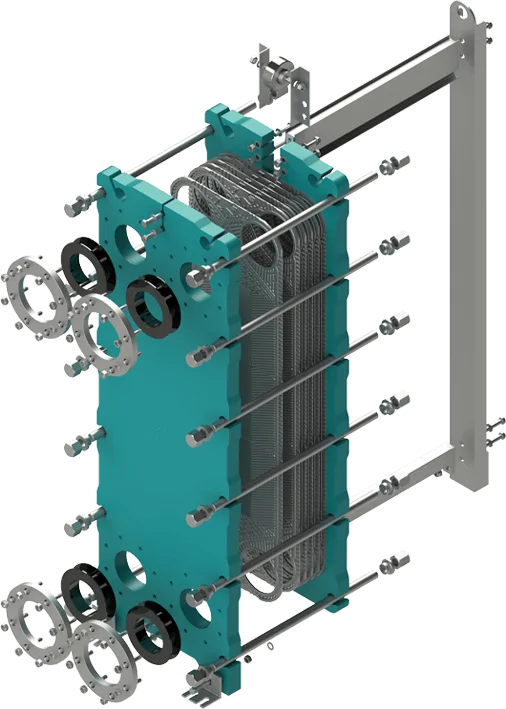

Plate heat exchangers, as the name suggests, are structures formed by bringing together a large number of metal plates separated by gaskets. These gaskets prevent the fluids from mixing and also allow the device to be easily disassembled and cleaned. The narrow channels between the plates create high turbulence, increasing heat transfer efficiency. These types of exchangers are widely preferred in HVAC, food, chemical, and industrial water systems due to their flexibility, ease of maintenance, and wide range of applications.

Brazed heat exchangers, on the other hand, are compact and integrated structures where the plates are bonded together with special brazing materials at high temperatures instead of gaskets. This design provides a great advantage in applications where sealing is critical or where high temperature and pressure conditions exist. Thanks to their gasket-free structure, they require low maintenance and offer high performance in much more compact sizes. Due to these features, brazed exchangers stand out in areas such as cooling systems, heat pumps, evaporators, condensers, and oil cooling applications.

The main difference lies in the flexible and modular structure of plate exchangers and the compact and sealed design of brazed exchangers. While plate models can be easily adapted to different flow and capacity needs, brazed models are resistant to high pressure and temperature due to their fixed structures. Therefore, when making a choice, the question should not be "which is better?" but "which is more suitable for which application?" In the continuation of this blog, we will compare the two types of exchangers in detail from different technical perspectives and examine why they should be preferred in which scenarios.

One of the most fundamental differences between plate and brazed heat exchangers is that their designs are developed to serve different process objectives. Both technologies perform the task of heat transfer, but their operating principles, fluid interaction, and design preferences respond to different industrial needs. Therefore, when deciding which type of exchanger to use, the question "what will it be used for?" is one of the most critical determining factors.

Heating Applications

Plate exchangers find a wide range of applications where it is necessary to increase the temperature of liquids or process fluids. Thanks to their modular structures, capacity can be easily increased by adding more plates. Additionally, they can be flexibly adapted to systems operating at different temperature ranges. For example, gasketed plate exchangers are frequently preferred in building heating systems, domestic water production, or process line pre-heating applications.

Brazed exchangers, on the other hand, stand out in compact systems requiring instant heating. Thanks to their gasket-free structures and high heat transfer coefficients, they offer high efficiency in applications where the temperature needs to be increased rapidly. With these features, they provide effective solutions in systems such as instant water heaters, hot gas heaters, and compact heating modules.

Cooling Applications

In cooling processes, significant differences also emerge between the two technologies. Plate exchangers are preferred in cooling towers, chiller circuits, and industrial water cooling systems due to their large heat transfer surface and high turbulence. Additionally, their easy disassembly and cleaning provide maintenance advantages in long-term operations.

Brazed exchangers, on the other hand, stand out in cooling applications requiring compact and high performance, such as heat pumps, evaporators, condensers, and oil cooling systems. Despite their small volume, they provide high heat transfer capacity, creating a great advantage especially in places where space is limited.

Circuit Separation and Pressure Breaking

One of the most important advantages of plate exchangers is their ability to separate two circuits from each other. In this way, heat transfer can be performed without the dirty or chemically aggressive fluid in one system coming into contact with the other circuit. This feature is of critical importance especially in industrial installations, central heating systems, and process lines. Additionally, they increase installation safety by balancing pressure differences in systems.

Brazed exchangers are generally not used for circuit separation because their structures are integrated and the physical separation between fluids is provided by brazed metal surfaces, not gaskets. However, when a reliable barrier is needed between two high-pressure fluids, brazed exchangers can also offer safe and leak-proof solutions.

Instant Heating and Systems Requiring Quick Response

Brazed exchangers stand out in applications where a quick response time is desired. Thanks to their compact structures, high surface area/diameter ratio, and low thermal masses, they can change the temperature of the fluid in a very short time. This feature provides a great advantage in systems such as evaporators, condensers, instant water heaters, and heat pumps.

Plate exchangers, on the other hand, are suitable for larger volume and continuously operating systems. Since their thermal masses are higher, their response times may be longer, but they offer superior performance in large-scale processes where stable and continuous heat transfer is required.

The answer to the question of which heat exchanger to use largely depends on the objectives of the process. While plate exchangers are the ideal solution in applications requiring large capacity and easy maintenance such as heating and cooling, brazed exchangers stand out in compact, quick-response systems operating under high pressure and temperature. Both technologies offer the highest efficiency in their respective fields; the important thing is to make a selection by correctly analyzing the system's objectives and operating conditions.

Fluid Properties: Viscosity, Particles, Corrosion Risk, and Material Compatibility

One of the most critical technical factors to consider when choosing between plate and brazed heat exchangers is the physical and chemical properties of the fluids they will work with. The efficiency of heat transfer, the lifespan of the device, and the frequency of maintenance are directly dependent on the viscosity of the fluid, the particles it contains, its chemical composition, and its corrosion potential. Therefore, when deciding which type of exchanger to use, not only the objective of the process but also the nature of the fluid should be analyzed in detail.

Viscosity and Flow Behavior

The viscosity of the fluid significantly affects the heat transfer coefficient and the flow profile inside the device.

• Plate heat exchangers can work compatibly with fluids of different viscosities thanks to their high turbulence flow and wide channel options. Especially for medium and high viscosity fluids, pressure losses can be controlled and sediment accumulation can be prevented thanks to specially designed wide-spaced plates. This feature provides an important advantage in applications such as processing viscous liquids like yogurt, honey, or fruit puree in the food industry.

• Brazed heat exchangers show the highest performance with low and medium viscosity fluids. Since their channel structures are narrower and fixed, high viscosity liquids can increase flow resistance and cause pressure losses. Therefore, they give ideal results with low viscosity fluids such as water, oil, refrigerant gases, and glycol.

Particle Content and Contamination

The solid particles or suspensions contained in the fluid also directly affect the choice of exchanger.

• Plate exchangers are more suitable for working with fluids containing particles thanks to their removable structures. Channel spacing can be widened and plates can be easily cleaned. This provides a significant advantage in systems working with dirty process water, open circuit cooling systems, or chemical solutions containing particles. Additionally, the maintenance process can be facilitated with periodic CIP (cleaning in place) systems.

• In brazed exchangers, narrow channels, high turbulence, and fixed structure pose a serious risk for particles. Suspensions and fibrous particles can cause clogging and pressure drop. Therefore, it is not recommended to use them with fluids containing particles without pre-filtration. They provide maximum efficiency when working with clean, particle-free, and filtered fluids.

Corrosion Risk and Chemical Compatibility

The chemical properties of the fluid play a decisive role in the material selection of the exchanger.

• Plate exchangers can be adapted to a wide variety of chemical environments with different material and gasket options. For example, AISI 316L stainless steel is ideal for general applications; titanium offers superior resistance in environments with high seawater or chloride content; SMO 254 or nickel alloys are preferred in aggressive chemical processes. The chemical compatibility of the gaskets with the fluid should also be ensured; different material options such as EPDM, NBR, or FKM are selected according to the type of fluid.

• In brazed exchangers, material selection is usually determined during production and cannot be changed later. Stainless steel plates and copper or nickel brazing are the most common combinations. Copper brazed models show excellent performance in neutral fluids like water and glycol; nickel brazed versions provide higher resistance against ammonia, acids, and other corrosive chemicals. Therefore, selecting the correct type of brazing is critically important if working with aggressive chemicals.

Fluid Compatibility and System Safety

Choosing the right type of exchanger and material not only affects performance but also system safety. The chemical structure and temperature of the fluid can directly affect the lifespan of the gaskets or brazed connections. Incorrect material selection can lead to risks such as leakage, corrosion, cracking, or thermal fatigue. Therefore, during the design phase, the pH value of the fluid, ion content, chloride level, and temperature range must be considered.

The physical and chemical properties of the fluid are among the most critical parameters in determining whether to use a plate or brazed heat exchanger. Plate exchangers, which offer easy maintenance advantages in high viscosity and particle-containing fluids, provide flexibility and a wide range of applications. In environments requiring clean, low viscosity, and high chemical resistance, brazed exchangers offer compact and high-performance solutions.

Temperature–Pressure Window: Which Type is Safe and Efficient at Which Limits?

One of the important differences between plate and brazed heat exchangers is the temperature and pressure ranges they can operate in. In addition to heat transfer efficiency, the safe and long-lasting operation of the device is directly dependent on these two parameters. Different design approaches and material structures give each type of exchanger certain advantages and limitations. Therefore, when deciding which type to use, it is of great importance to analyze the limits of the system's operating conditions in detail.

Temperature Ranges: Thermal Resistance and Process Compatibility

Plate heat exchangers can generally operate safely in the range of -20 °C to +180 °C. This wide range makes them suitable for many applications, from heating and cooling systems to process lines. Gaskets play a decisive role at this point: the working temperature range may vary depending on the gasket material used. For example, EPDM gaskets are suitable for medium temperature ranges, while FKM gaskets provide stable performance at higher temperatures. However, since gaskets have thermal expansion and aging limits, gasketed systems can become risky in applications where very high temperatures are involved.

Brazed heat exchangers, on the other hand, can operate safely at much higher temperatures thanks to their gasket-free structures. They generally offer efficient performance in the range of -196 °C to +200 °C, and in some special designs, this value can go up to +250 °C. This feature makes them ideal for high-temperature steam lines, instant heating systems, or high-temperature gas applications. Additionally, since they maintain their structural integrity at very low temperatures, they are also preferred in cryogenic applications.

Pressure Ranges: Mechanical Strength and Safety

There are also significant differences between the two types of exchangers in terms of pressure resistance.

In plate exchangers, gaskets can be the weak point of the system under high pressure. Standard models are generally designed to operate in the range of 10–16 bar; with special reinforcements, this value can be increased to 25 bar. However, they are not suitable for very high-pressure applications because the risk of gasket deformation increases and sealing weakness may occur. Therefore, plate models are the ideal solution in building heating systems, industrial water circuits, or medium-pressure process lines.

Brazed exchangers can withstand much higher pressures thanks to their compact and integrated structures. Typical operating pressures can go up to 30 bar, and test pressures can reach up to 45 bar. This level of resistance provides a critical advantage for high-pressure refrigerant circuits, oil cooling systems, power plant applications, or high-pressure conditions in chemical processes. Additionally, since there are no gaskets, pressure fluctuations do not affect the structural integrity of the device.

Temperature and Pressure Combinations: Choosing the Right Type

When the operating temperature and pressure of the system are evaluated together, it becomes clear which type of exchanger will be more suitable:

• Low–medium temperature and pressure range (e.g., 60–120 °C and 6–12 bar): Plate exchangers perform excellently here because they provide the advantage of easy maintenance, flexibility, and a wide range of applications.

• High temperature and pressure (e.g., 150–200 °C and 20–30 bar): Brazed exchangers work much more safely and efficiently under these conditions because there is no risk of leakage since there are no gaskets, and structural integrity is maintained.

• Very low temperatures (e.g., cryogenic applications, -150 °C): The integrated structure of brazed exchangers stands out here as well because the risk of deformation due to thermal expansion is minimized.

Long-Term Effects of Thermal and Mechanical Resistance

Failure to correctly analyze temperature and pressure ranges can seriously shorten the lifespan of the device. An incorrectly selected exchanger can lead to:

• Premature aging and leaks in gaskets,

• Cracking of plates due to thermal expansion,

• Fatigue cracks in brazing points,

• And most importantly, risking process safety.

Therefore, in system design, not only nominal operating conditions but also peak values and fluctuations should be considered. Especially in processes where sudden pressure increases occur, brazed exchangers offer more stable and safe performance, while in low-pressure systems requiring frequent cleaning, plate exchangers are more sustainable in the long run.

Temperature and pressure values are critical determinants in the choice between plate and brazed heat exchangers. While plate models offer ideal solutions for low and medium-level operating conditions, brazed models stand out in challenging processes requiring high temperature and pressure in terms of safety and efficiency. When the boundary conditions of the system are correctly analyzed, both technologies provide maximum performance in their respective fields.

Heat Transfer Performance and Pressure Loss: Turbulence, Channel Geometry, and Efficiency

One of the most important technical differences that distinguish plate and brazed heat exchangers from each other is heat transfer performance and the associated pressure loss behavior. While both types provide heat transfer between two fluids, parameters such as plate arrangement, channel geometry, and the level of turbulence of the flow play a decisive role in this performance. In this section, let's try to understand which scenario is more advantageous by examining the heat transfer capabilities of both types of exchangers and their behavior against pressure losses in depth.

The Relationship Between Turbulence and Heat Transfer

The effectiveness of heat transfer is largely related to the flow type of the fluid, that is, whether it is laminar or turbulent flow. Turbulence increases the heat transfer coefficient by increasing the contact of the fluid with the plate surfaces.

• In plate heat exchangers, high turbulence is created thanks to specially shaped corrugated (chevron) plates. The angle and geometry of the plates allow the fluid to progress turbulently along the plate surface. This makes it possible to use the heat transfer area effectively and also reduces fouling. Additionally, thanks to turbulent flow, the heat transfer coefficient can reach levels of 3000–7000 W/m²K. This value is several times higher compared to traditional tubular systems.

• In brazed heat exchangers, since the channel structure is narrower and more compact, the flow naturally becomes turbulent. This situation allows obtaining a high heat transfer coefficient even at lower flow rates. Since the channel geometry is fixed, performance is stable, and it is ensured that the level of turbulence remains constantly high. This feature provides an important advantage especially in instant heating-cooling and compact systems.

Channel Geometry and Flow Path Design

Channel design is another factor that directly affects both heat transfer efficiency and pressure loss.

• In plate exchangers, plate patterns and placement angles extend the flow path of the fluid, increasing the contact time. The longer the fluid travels along the plate surface, the more heat transfer is possible. Additionally, the flow type (counterflow, parallel flow, crossflow) can be easily adjusted by changing the plate arrangement, allowing optimization according to different process needs.

• In brazed exchangers, the channel structure is fixed but quite dense. Thanks to narrow channels, the heat transfer surface/area ratio is high, and the contact time of the fluid increases. This structure allows reaching very high heat transfer coefficients despite compact dimensions. However, since the channel geometry is fixed, flexibility in design is limited; the capacity or flow direction of the system cannot be easily changed later.

Pressure Loss and Flow Resistance

As heat transfer performance increases, pressure loss also generally increases. Therefore, a balance between heat transfer and pressure loss is considered in the design of both types of exchangers.

• Plate exchangers can cause more pressure loss due to high turbulent flow. However, these losses can be controlled thanks to wide channel options and optimized plate patterns. Additionally, by increasing the number of plates, the same heat load can be distributed over a larger surface, which can reduce pressure loss. In high flow rate systems, optimum balance is achieved by increasing channel width.

• In brazed exchangers, since the channel spacing is narrow, flow resistance is generally higher. This situation can increase pressure loss but also raises turbulence, maximizing the heat transfer coefficient. Therefore, in brazed exchangers, pressure loss often comes with high heat transfer. This structure provides an advantage in low flow rate and high-pressure systems, while in high flow rate systems, the pump power may need to be increased.

Efficiency Comparison

• Plate heat exchangers offer high efficiency in large flow rates and variable loads thanks to their wide surface area and optimizable channel structures. Therefore, they are preferred in building heating systems, process water lines, and large-scale industrial applications.

• Brazed exchangers provide very high heat transfer efficiency in small volumes thanks to their compact sizes, high turbulence, and narrow channels. With these features, they are ideal solutions for cooling cycles, heat pumps, oil coolers, and evaporator-condenser systems.

Effects on Performance and Energy Consumption

High heat transfer performance allows the system to perform the same heat load with a smaller surface area and less energy. This situation reduces energy costs and makes it possible to reduce device sizes. However, since the pump power requirement of high-performance systems may also increase, pressure losses must be considered in the design. While plate exchangers offer more balanced performance at higher flow rates, brazed exchangers provide high efficiency at smaller flow rates.

Both types of exchangers can offer high heat transfer performance but achieve this in different ways. Plate exchangers offer flexible solutions in variable loads and large flow rates thanks to their adjustable channel structure, while brazed exchangers achieve high performance in narrow spaces with their compact structures. In terms of pressure loss, although flow resistance is naturally higher in brazed exchangers, this situation increases heat transfer efficiency. Considering this balance in the design phase directly affects the overall efficiency of the system and operating costs.

Sealing and Process Safety: Gasket Architecture, Double-Safety Plates, and Brazed Integrity

Sealing in heat exchangers is of critical importance not only for the efficiency of the device but also for the overall safety of the system and the continuity of operation. The mixing of fluids at different temperatures can lead to product quality deterioration, process stoppages, and even system failures and safety risks. Therefore, one of the most fundamental differences between plate and brazed heat exchangers is how the fluids are separated from each other and how sealing is achieved.

In this section, we examine the sealing design, potential risks, and safety strategies of both technologies in detail.

Gasket Architecture in Plate Heat Exchangers

The most distinctive feature of plate heat exchangers is that the fluids are separated from each other by gaskets. The gaskets surrounding each plate ensure sealing while also directing the fluids to pass through the designated channels. The most important advantage of this design is that the gaskets can be easily replaced during maintenance and cleaning processes.

Gaskets are usually selected from materials suitable for the chemical properties of the fluid and temperature–pressure conditions:

• EPDM gaskets are compatible with hot water, steam, and neutral fluids.

• NBR is ideal for oil and hydrocarbon-based fluids.

• FKM (Viton) provides high resistance against high temperatures and aggressive chemicals.

Thanks to the modular structure of the gasket system, high flexibility is achieved in terms of sealing. Additionally, in gasketed plate exchangers, double-safety plate designs are used to prevent fluids from mixing even in the event of a gasket failure. In this special design, the leak is discharged outside, and the system gives an alarm to alert the maintenance team. This safety detail is of critical importance especially in the food, pharmaceutical, and chemical sectors.

However, gasketed systems also have disadvantages: under high temperature and pressure, gaskets can harden over time, become deformed, or lose their sealing properties due to aging. Therefore, regular maintenance and periodic gasket replacement are mandatory to maintain system safety.

Sealed Integrated Structure in Brazed Heat Exchangers

In brazed heat exchangers, the gaskets are replaced by plates joined by brazing at high temperatures. This production method ensures that the fluid channels are formed in a completely metallic structure in a leak-proof manner. The plates are usually brazed with metals such as copper or nickel, which have high conductivity and durability properties.

This integrated structure offers a very high level of safety in terms of sealing. Since there are no gaskets:

• The risk of leakage due to factors such as thermal expansion, chemical wear, or aging is eliminated.

• Stability is maintained under high pressure and temperature conditions.

• Sealing continues for many years without requiring maintenance.

Additionally, since the fluids are completely surrounded by metal surfaces, the risk of cross-contamination is minimized. This feature provides a great advantage especially in environments such as refrigerant circuits, oil cooling systems, high-pressure condenser–evaporator applications, and chemical process lines.

However, the disadvantage of brazed exchangers is that due to the integrated structure, the possibility of repair and intervention is limited. A possible sealing problem usually requires the replacement of the device. Additionally, since access to internal surfaces is not possible, cleaning processes are more difficult compared to plate exchangers; therefore, it is recommended to use them only with clean, particle-free fluids.

Effects on Process Safety

Choosing the right sealing solution directly affects not only the lifespan of the device but also process safety and product quality.

• In environments where cross-contamination is unacceptable, such as the food and pharmaceutical sectors, double-safety plate systems or the sealed structure of brazed exchangers are preferred.

• In processes with high pressure, sudden temperature changes, or aggressive chemicals, the gasket-free brazed structure is a safer and longer-lasting solution.

• In facilities where periodic maintenance can be easily performed and flexibility is required, gasketed systems provide practicality.

Conclusion: Positioning the Right Exchanger Type for Different Processes

Although plate and brazed heat exchangers perform the same basic task of providing heat transfer between two fluids, they are quite different in terms of design philosophy, usage purposes, and technical features. These differences reveal the fact that a single device cannot be the "best" for every application. The correct selection should always be made by considering the needs of the system, process conditions, and operational priorities.

Plate heat exchangers stand out in systems requiring flexibility and ease of service. Thanks to their modular structures, they adapt to capacity changes, and the number of plates can be increased to easily expand the heat transfer area. Their gasketed structures make cleaning and maintenance processes quick and practical. These features make them ideal for HVAC applications, process water lines, the food and beverage industry, chemical process circuits, and circuit separation systems. They also provide an advantage in working with fluids with high particle content or where sediment formation is expected over time.

Brazed heat exchangers, on the other hand, offer reliable performance even in challenging conditions thanks to their compact structures and sealed designs resistant to high pressure and temperature. Their gasket-free structure minimizes maintenance needs and ensures that fluids are completely isolated within metallic channels. These features make them the most suitable solution for cooling systems, heat pumps, evaporator-condenser applications, oil cooling circuits, energy recovery systems, and high-pressure process lines. Additionally, they are unique in terms of providing high performance in small volumes where space is limited.

Evaluating these two technologies as complementary solutions rather than competitors would be the most accurate approach. In large-scale facilities or complex processes, both types are often used in the same system for different tasks. For example, while a plate exchanger is preferred for heating high-flow water in the main circuit, a brazed model can be used in the heat pump of the same system.

In conclusion, the correct selection of a heat exchanger is only possible by carefully analyzing not only the technical features but also the process objectives, fluid properties, maintenance strategies, and operational priorities. While plate systems offer flexible and service-friendly solutions, brazed models stand out with their compact, sealed, and high-performance structures.