Lobe pumps are one of the types of positive displacement pumps used in industry, especially in fluid transfers requiring hygiene, reliability, and flexible use. The basic principle of positive displacement pumps is to capture a specific volume and transfer this volume to the discharge line. Lobe pumps operate on the same principle; however, unlike other pump types, they perform this process through specially shaped rotors rotating without contact inside the body. This design allows the pump to operate both precisely and powerfully.

One of the most important features of lobe pumps is their valve-less structure. This means there are no valves or gates directing the flow of fluid. Instead, the volume changes occurring during the rotation of the rotors enable the movement of the fluid. This allows the pump to offer high efficiency with a simple mechanism. Additionally, the valve-less design reduces the risk of failure, simplifies maintenance processes, and extends the pump's lifespan.

To examine the working principle step by step; there are usually two or three lobe rotors inside the lobe pump body. These rotors rotate synchronously without contacting each other inside the pump body. As the rotors rotate, a volume expansion occurs on the suction side, creating a vacuum at the pump's inlet. The vacuum draws the fluid into the pump body. As the rotors continue to rotate, the fluid passes through the body and is directed to the discharge side. With the volume contraction at the discharge part, the fluid is pushed forward along the line, completing the transfer.

Thanks to this working principle, lobe pumps perform seamlessly with low, medium, and high viscosity fluids. For example, low-density beverages, fluid viscous dairy products, or high-viscosity products like jam and molasses can be safely transferred with the same pump. The positive displacement feature ensures that every fluid is transported with a stable flow rate, regardless of viscosity.

Another important advantage of lobe pumps is that they transfer the fluid without damaging its structure. Since the rotors operate without contacting each other, there is no friction on the product surface, which is critically important, especially for the food and pharmaceutical industries. Sensitive products like fruit juice, yogurt, cream, chocolate, honey, and glucose syrup can be pumped without altering their structure, nutritional values, or consistency. This feature also allows the pump to perform reliably with abrasive or sticky fluids.

In sectors where high hygiene standards are required, the designs of lobe pumps are generally made from AISI 316 stainless steel material. This material offers high corrosion resistance and is considered safe for contact with food. Additionally, since lobe pumps are produced to be compatible with CIP (Cleaning in Place) systems, they can be easily cleaned without being disassembled along the pump line. This is a significant advantage, especially for ensuring production continuity and hygiene safety in the food and pharmaceutical sectors.

In conclusion, lobe pumps have gained a wide range of applications in the industry thanks to their simple yet effective working principles. Their valve-less structure, positive displacement operation logic, ability to transport fluids of different viscosities without issues, and capability to transfer without damaging the product structure have made them indispensable equipment in modern production processes. Whether in processes requiring hygiene or challenging industrial applications, lobe pumps stand out for their reliability and efficiency.

Lobe pumps are durable pumps that can be safely used in both hygienic and industrial processes, thanks to their seemingly simple yet detailed engineering design. Their structural features reveal why they are preferred in different sectors and how they differ from other pump types.

The most basic component of the pump, the body, is usually made from AISI 316 stainless steel. This material is considered mandatory for safety in the food and pharmaceutical industries and also shows high resistance to chemical corrosion. The body is designed to ensure that the surfaces in contact with the fluid are completely smooth and easy to clean. This prevents fluid from sticking to the surface or bacteria from growing. The hygienic design is developed to be compatible with CIP (Cleaning in Place) and SIP (Sterilization in Place) systems.

The most striking structural feature of lobe pumps is the rotor design. Inside the body, there are two or three lobe rotors that rotate without contacting each other. The rotors move synchronously, and during this movement, the fluid is transported inside the body. Different rotor types (two-lobe, three-lobe, butterfly type, and single butterfly rotor) offer solutions suitable for different fluids and process needs. For example, a two-lobe rotor is ideal for fluids containing solid particles because it allows transfer without crushing the particles and damaging the product.

Another critical component of the pump is the shaft and bearing system. The shaft, made from AISI 316 stainless steel, shows high durability and does not deform during long-term use. The bearings ensure the synchronized movement of the rotors while minimizing vibrations. This allows the pump to operate quietly and have a long lifespan.

The bodies of lobe pumps can also be equipped with heating jackets upon request. Heating jackets are designed to prevent the fluid from freezing or losing its consistency in the pump. Especially for high-viscosity fluids like chocolate, honey, or molasses, the body is heated to facilitate the flow of the product and enhance pump performance.

Connection types are also important in terms of structural flexibility. Lobe pumps are offered with threaded, flanged, or food-grade union connections. Thus, they can be easily integrated into different piping systems. Additionally, the pumps have both side inlet/outlet and top inlet/bottom outlet configurations. This design flexibility provides significant advantages in plant planning.

On the outer surface, there is usually a gear box made of cast iron protected with epoxy paint. This box protects the mechanical components of the pump from external factors while also increasing durability during long-term use.

In summary, the structural features of lobe pumps; stainless steel body, contactless synchronized rotors, strong shaft structure, optional heating jackets, and different connection options make them suitable for both hygienic and industrial applications. These features ensure that the pumps are not only reliable but also user-friendly and long-lasting.

Rotor Options and Usage Advantages

One of the most important parts of lobe pumps is their rotors. The pump's performance, the type of fluid being transferred, and the system's efficiency are directly related to the rotor design. Lobe pumps are produced with various rotor options to meet different application requirements, and each rotor type offers unique advantages.

The most commonly used rotor type is the two-lobe rotor. This design provides significant advantages, especially in fluids containing solid particles. For example, in products like jam, fruit-particulate sauces, or molasses, the two-lobe rotor transfers the particles within the fluid without crushing or damaging them. This feature is critically important for maintaining product quality in the food industry.

Three-lobe rotors ensure a more balanced and vibration-free flow. This type of rotor is preferred in applications requiring higher flow rates and more precise flow control. The three-lobe structure also offers the advantage of quiet operation by reducing the pump's vibration level. Especially in hygienic processes, these rotors allow seamless transfer while preserving product integrity.

Another option is butterfly rotors. This rotor type is designed to transfer sticky or sensitive fluids with minimal damage to the product surface. For example, sensitive fluids like chocolate, cream, or cosmetic products can be pumped without losing their consistency thanks to the butterfly rotor. Additionally, since the butterfly rotor has a larger contact surface with the fluid, high efficiency is achieved even at low speeds.

Single butterfly rotors used for more specific applications stand out, especially in processes where low flow but sensitive product transfers are made. This rotor type ensures transfer with minimal damage to the product, preserving its physical or chemical properties.

The variety offered by rotor options makes it possible for lobe pumps to be widely used in different sectors. Users can achieve maximum efficiency from the pump by selecting the most suitable rotor type according to the fluid's structure and process needs. Additionally, all rotors are produced from stainless steel material, meeting high standards in terms of hygiene and durability.

In conclusion, the diversity in rotor design of lobe pumps ensures seamless transfer in fluids containing solid particles, sticky, abrasive, or sensitive fluids. While the two-lobe rotor offers a particle-friendly solution, the three-lobe rotor provides a more balanced flow, and the butterfly rotor offers maximum protection in sensitive products. This flexibility has made lobe pumps indispensable in both food and industrial applications.

Hygienic Design and FDA Approval

One of the main reasons lobe pumps are preferred is their ability to meet the needs of sensitive sectors such as food, pharmaceuticals, and cosmetics, thanks to their hygienic designs. These pumps not only provide fluid transfer but also operate in compliance with hygiene standards without damaging the product.

The foundation of hygienic design lies in the choice of materials used. All surfaces of lobe pumps in contact with the fluid are generally made from AISI 316 stainless steel. This material is one of the most suitable options for food safety because it shows high resistance to corrosion, does not react chemically, and does not allow bacteria to grow on its surface. Additionally, its smooth surface structure ensures the fluid passes through the pump without leaving any residue.

Another important aspect of hygienic design is ease of cleaning. Lobe pumps are designed to be compatible with CIP (Cleaning in Place) and SIP (Sterilization in Place) systems. This allows cleaning and sterilization processes to be carried out along the line without disassembling the pump. This feature provides a significant advantage in terms of production continuity, especially in the food and pharmaceutical industries. The easy-to-clean structure of the pump increases both work safety and guarantees product safety.

The international certification of hygiene standards is also of critical importance. MIT and INOXEN branded lobe pumps have FDA (U.S. Food and Drug Administration) approval. FDA approval proves that these pumps are manufactured in a way that will not harm human health when in contact with food and that the materials used meet hygiene criteria. This shows manufacturers that their products can be safely used in both local and global markets.

Moreover, hygienic design not only directly contributes to the food sector but also to the cosmetics and pharmaceutical industries. Sensitive products such as creams, lotions, syrups, or medical fluids are transferred without undergoing any structural degradation in the pump. This ensures the quality of the product is maintained, shelf life is extended, and user safety is guaranteed.

In conclusion, the hygienic design and FDA approval of lobe pumps make them not only a pump but also equipment that offers a guarantee of quality and safety. Since meeting hygiene standards is mandatory in the food and pharmaceutical industries, lobe pumps stand out as one of the most reliable solutions in these areas.

Material Structure and Durability

One of the most important factors behind the widespread use of lobe pumps in the industry is their durable material structures. Because pumps have to work with fluids that have very different characteristics; these fluids can sometimes be abrasive, sometimes sticky, or sometimes liquids exposed to high temperatures. In such cases, the reliability of the pump is directly dependent on the quality of the materials used.

All surfaces of lobe pumps in contact with the fluid are generally made from AISI 316 stainless steel. This material is one of the safest options, especially preferred in the food and pharmaceutical industries. Thanks to its high corrosion resistance, the risk of deformation is minimized when working with saline water, acidic solutions, or chemically-laden fluids. Additionally, the smooth surface of stainless steel prevents the growth of bacteria and microbes; this is of critical importance for sectors requiring hygienic use.

One of the most important parts of the pump, the rotors, is also manufactured from stainless steel. The durability of the rotors allows for long-term trouble-free operation regardless of the characteristics of the product being pumped. For example, sticky products like jam, honey, or molasses do not damage the rotor surface, while chemical fluids cannot penetrate the stainless steel structure.

Besides, the shaft and gear box supporting the pump body are also protected with special materials. While the shaft is made from stainless steel, the gear box is usually made of cast iron and protected with an epoxy paint coating. This coating provides additional durability against external environmental conditions and factors such as moisture and oil. Thus, the pump works in harmony not only with the fluid but also with external environmental conditions for many years.

The durability of lobe pumps is not limited to material selection; engineering design also extends their lifespan. Thanks to the contactless rotor structure, the rotors do not rub against each other, and wear does not occur. This not only increases the lifespan of mechanical parts but also prevents the structure of the pumped fluid from deteriorating. Additionally, the bearings inside the pump reduce vibration, contributing to quiet and balanced operation.

In conclusion, the material structure of lobe pumps makes them suitable for both hygienic and industrial challenging conditions. Thanks to stainless steel surfaces, epoxy-protected gear boxes, and contactless rotor design, these pumps offer a long-lasting, reliable, and low-maintenance solution.

Seal and Leakage Solutions

The reliability of a pump is measured not only by its rotor and body structure but also by its sealing systems. Lobe pumps are equipped with various seal solutions that can adapt to different fluid types and process requirements. This prevents fluid loss and maintains hygiene and safety standards.

One of the most commonly used options in lobe pumps is the mechanical seal. This system prevents fluid from leaking out by the contact of rotating and stationary surfaces. Mechanical seals stand out for their low maintenance needs and high reliability. In food and beverage applications, hygienic design mechanical seals are preferred to ensure product safety.

For more challenging applications, a double (flushed) cartridge mechanical seal is used. In this system, there are two sets of seals, and a barrier fluid is provided between them to maximize sealing. This design is preferred especially in products with high viscosity or a tendency to crystallize. For example, jam, glucose, or sugary fluids can be easily transferred inside the pump thanks to the double mechanical seal, preserving product quality and extending the pump's lifespan.

Another option used in some industrial processes is the carbide seal. Seals made from carbide material show high durability in fluids with abrasive properties. In the chemical, petrochemical, and pharmaceutical industries, these seals are preferred when working with corrosive or aggressive fluids.

Sealing systems are important not only for safety but also for energy efficiency and ease of maintenance. Effective sealing keeps the pressure inside the pump balanced, prevents energy losses, and allows the pump to operate more efficiently. Additionally, the modular structure of seal options allows them to be easily replaced when necessary. This shortens maintenance times and reduces operating costs.

In conclusion, the seal and leakage solutions offered by lobe pumps make them reliable in both sensitive sectors requiring hygiene and challenging industrial applications. Whether ensuring full hygiene in food processes or achieving high safety in chemical environments, lobe pumps exhibit optimal performance under all conditions with the right seal selection.

Heated Jacket Lobe Pumps

One of the most important flexibilities offered by lobe pumps is the heating jacket option. This feature plays a critical role, especially in the transfer of high-viscosity fluids, those at risk of freezing, or those that need to remain at a specific temperature. Heating jackets consist of special compartments integrated onto the pump body or cover. Hot water, steam, or thermal oil is passed through these compartments to keep the temperature of the fluid inside the pump under control.

Heated jacket pumps are preferred especially for high-viscosity products like chocolate, honey, molasses, glucose syrup, oils, and resins. These types of products tend to solidify or lose their fluidity at low temperatures. Thanks to the heating jacket, the fluid is kept at a constant temperature inside the pump, preventing freezing and ensuring a smooth transfer process. Additionally, the consistency of the product is not altered during pumping, which enhances both quality and process efficiency.

Heating jackets can be applied in three different types:

• The heating jacket on the body provides general temperature control of the fluid by heating the entire body of the pump.

• The heating jacket on the cover helps maintain temperature at the fluid's inlet and outlet points.

• The heating jacket used on both the body and cover is preferred in special processes requiring more precise temperature control.

This feature not only eliminates the risk of freezing but also ensures the product is processed at a constant temperature throughout the process. For example, chocolate or some chemical substances remain more homogeneous when processed at a specific temperature, and product quality is not compromised.

Heated jacket lobe pumps also offer advantages in terms of operational safety. Blockages and pressure increases that may occur inside the pump due to freezing are prevented, protecting the equipment from damage. This reduces maintenance costs and extends the pump's lifespan.

In conclusion, heated jacket lobe pumps are the ideal solution, especially for the transfer of high-viscosity or temperature-sensitive fluids. They are an indispensable option for companies that want to ensure process continuity, maintain product quality, and increase operational safety.

Advantages of Lobe Pumps: Why Are They Preferred?

Lobe pumps have many advantages that make them widely used in different sectors of the industry. These advantages are not only limited to pump performance; they are also directly related to factors such as hygiene, energy efficiency, ease of maintenance, and long lifespan.

One of their biggest advantages is their ability to work compatibly with fluids of different viscosities. They provide seamless transfer across a wide range, from low-density liquids to high-viscosity products. For example, in addition to fluid products like milk or fruit juice, sticky and dense products like honey, jam, molasses, or oil can also be safely transported with the same pump. This flexibility is one of the most important features that distinguish lobe pumps from other pump types.

Another important advantage is their ability to preserve product sensitivity. The operation of rotors without contacting each other does not cause friction on the fluid's surface. This ensures the preservation of the structural properties of the product. In the food industry, creams, yogurt, chocolate, or active ingredients in the pharmaceutical sector that should not have their consistency altered are pumped without damage.

Lobe pumps also stand out with their structures that provide full hygiene. Thanks to their stainless steel bodies, smooth surfaces, and compatibility with CIP/SIP systems, they are easy to clean. Their FDA-approved hygienic designs provide safe use in food and pharmaceutical production. This feature is a significant advantage for manufacturers who want to meet quality standards in global markets.

Energy efficiency is also one of the reasons lobe pumps are preferred. Their positive displacement working principle ensures a constant flow at every revolution, minimizing energy losses. Their quiet operation, low vibration levels, and long-lasting bearing systems also increase operational efficiency.

Finally, lobe pumps stand out with their ease of maintenance and low operating costs. Their modular structures allow seals, rotors, or other parts to be easily replaced when necessary. This shortens maintenance times and prevents interruptions in production.

Considering all these advantages, lobe pumps are evaluated as not just a pump but also as strategic equipment that offers a guarantee of efficiency, hygiene, and reliability. These features have made them indispensable in both sensitive sectors like food and challenging industries like chemicals, textiles, or energy.

Application Areas of Lobe Pumps

One of the most notable features of lobe pumps is their very wide range of applications. Thanks to their positive displacement structures, they can safely transfer fluids of different viscosities. Their hygienic designs provide an advantage for the food and pharmaceutical industries, while their durable structures offer reliability in harsh conditions such as chemicals and textiles. This diversity makes lobe pumps indispensable in both processes requiring hygiene and industrial applications.

Food Industry

The food sector is one of the primary areas where lobe pumps are most commonly used. Products such as dairy products, yogurt, cream, honey, jam, fruit juice, chocolate, and syrup can be pumped without compromising their sensitive structures. Full food safety is ensured thanks to hygienic design, compatibility with CIP/SIP systems, and FDA approval. Additionally, their ability to carry medium-sized solids allows for the seamless transfer of products with fruit particles.

Petrochemical and Pharmaceutical Industry

Lobe pumps are a strong alternative for aggressive chemicals, corrosive fluids, or systems operating at high temperatures. Their stainless steel structures and durable seal solutions ensure these pumps are used for a long time. In the pharmaceutical industry, syrups, sugary solutions, and sensitive fluids are pumped while preserving product characteristics. This enhances both quality and safety.

Textile Sector

Fluids used in dyeing, finishing, printing, and coating processes are often sticky, viscous, or chemically laden. Lobe pumps efficiently transfer these fluids without altering the product's structure. Additionally, they contribute to a more controlled process by providing a constant flow rate.

Transportation and Tanker Applications

The feature of lobe pumps being mounted on a portable chassis makes them very useful, especially in filling and emptying operations of food tankers. The pump can operate by taking energy from the vehicle and provides easy use in field conditions. The unloading of high-viscosity products from tankers is done quickly and safely thanks to these pumps.

Other Industrial Uses

Lobe pumps are also preferred in cosmetics, energy production, chemicals, and even environmental technologies. In the cosmetics sector, creams and lotions are transferred without compromising product quality; in the energy sector, oils and dense liquids are safely transported. In chemical processes, corrosive and aggressive fluids can be pumped safely thanks to durable material options.

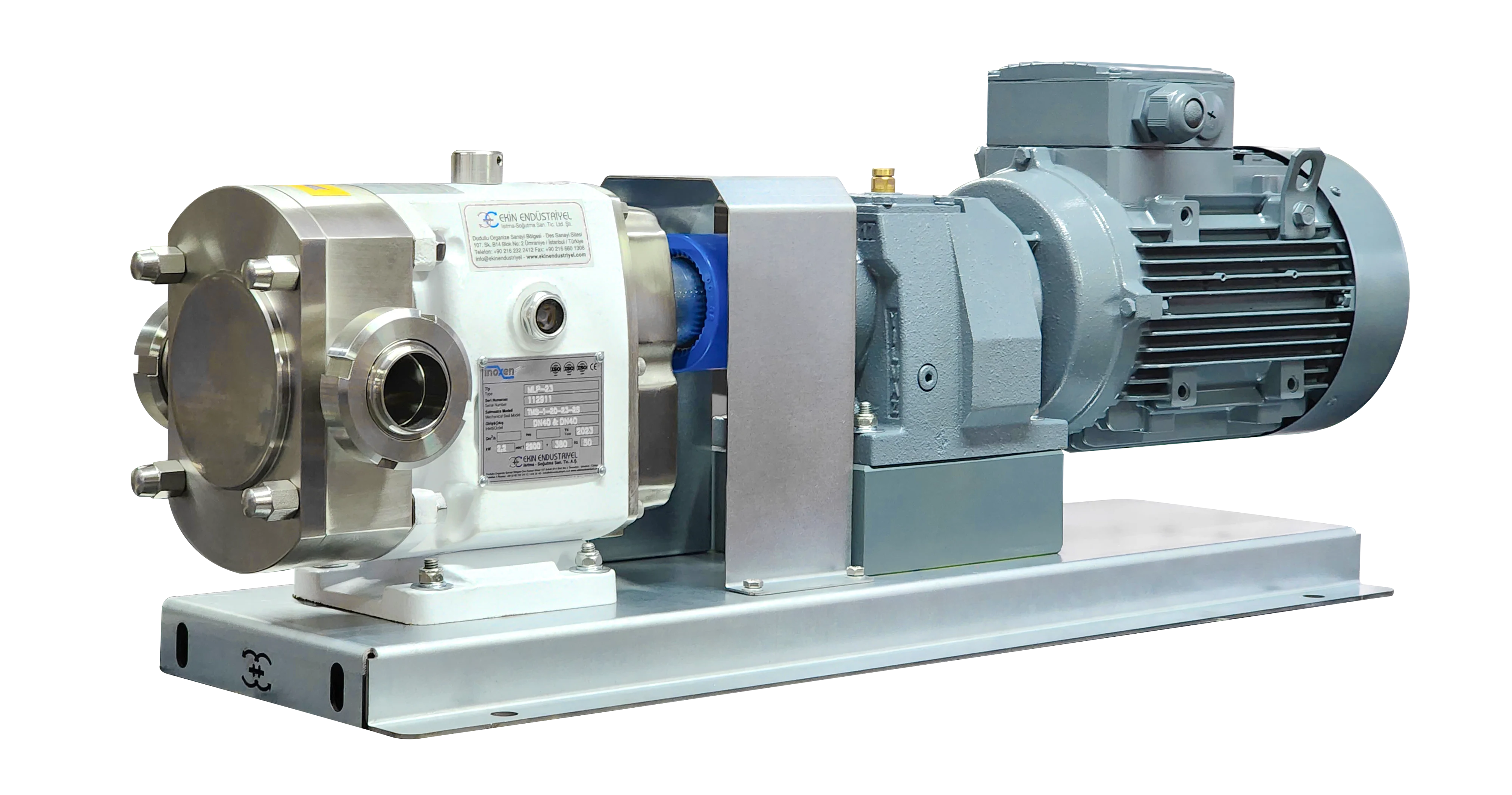

INOXEN Lobe Pump Solutions

INOXEN, a strong brand in lobe pumps, develops special solutions for both hygienic and industrial applications. Previously known with the MIT brand, these products have been responding to users' needs in recent years with their modernized designs under the INOXEN name.

INOXEN Lobe Pumps offer reliability, durability, and high performance with designs suitable for the needs of different sectors. Produced in the capacity range of 0–65 m³/h, these pumps ensure the safe transfer of low, medium, and high viscosity products. Thanks to their hygienic design and FDA approval, they allow the transportation of sensitive products such as dairy products, yogurt, jam, honey, fruit juice, and similar without compromising quality. Additionally, their structure that can be specially designed for customer processes offers solutions suitable for different production needs.

INOXEN Lobe Pumps, which provide reliable performance even under challenging conditions, are successfully used in areas such as chemicals, pharmaceuticals, and textiles as well as in the food sector. Thanks to the heating jacket option, the fluid can be kept at a constant temperature, and high-viscosity products can be pumped without issues. Their quiet operation, low maintenance needs, and energy efficiency offer long-term advantages to businesses.

INOXEN Lobe Pumps can adapt to every application with different rotor options, various seal solutions, and flexible connection types. Their durable material structure (AISI 316 stainless steel) and modular design offer long-lasting use and ease of maintenance.

In conclusion, INOXEN lobe pumps offer modern industrial solutions with their hygienic design, flexible usage options, and high performance. Whether in hygiene-focused sectors like food and pharmaceuticals or in challenging industrial areas like chemicals and textiles, INOXEN pumps, developed with the experience gained from the MIT brand, are a reliable and efficient choice.

Maintenance Ease and Operational Efficiency

One of the strongest aspects of lobe pumps is not only their ability to provide high performance but also the advantages they offer in terms of maintenance ease and operational efficiency. In industrial facilities, the long-term trouble-free operation of pumps is of critical importance for production continuity and cost optimization. Lobe pumps stand out in this regard with their user-friendly structures.

One of the most important advantages of the pump is its modular design. Rotors, seals, and other essential parts can be easily disassembled and renewed when necessary. This feature shortens maintenance time, preventing interruptions in production. Especially in hygienic processes, their compatibility with CIP (Cleaning in Place) and SIP (Sterilization in Place) systems allows the pumps to be cleaned without disassembly. This saves time and maintains hygiene standards.

The low wear rate design of lobe pumps ensures long-lasting use. Since the rotors do not contact each other, wear from friction does not occur. This not only reduces the frequency of maintenance but also contributes to preserving the structure of the fluid. While product quality is not compromised, the lifespan of the pump parts is also extended.

From an operational efficiency perspective, lobe pumps stand out with their energy-saving structures. Their constant and balanced flows prevent pressure fluctuations in pump systems. Their quiet operation makes the working environment more comfortable and reduces equipment wear caused by vibration.

Additionally, maintenance ease means low total ownership cost for businesses. With fewer failures, shorter maintenance times, and longer spare part life, lobe pumps offer cost-effective solutions in the long run. This is an important advantage for both small-scale businesses and large industrial facilities.

In conclusion, the maintenance ease and high operational efficiency offered by lobe pumps make them indispensable not only in terms of performance but also in terms of economic and sustainable solutions.

Conclusion: A Reliable, Hygienic, and Efficient Fluid Transfer Solution

Lobe pumps are one of the most flexible and reliable pump solutions that can meet the different needs of modern industry. While they provide seamless performance in the transfer of low, medium, and high viscosity fluids thanks to their positive displacement structures, they ensure safe flow without damaging the product's structure. This feature has made them indispensable, especially in sectors where product sensitivity is critical, such as food, pharmaceuticals, and cosmetics.

Thanks to their hygienic designs, the use of AISI 316 stainless steel material, and FDA approvals, lobe pumps offer safe use at international standards. Their compatibility with CIP and SIP systems facilitates cleaning and sterilization processes in production lines, elevating hygiene safety to the highest level. At the same time, ease of maintenance and low failure rates create significant cost advantages for businesses in the long run.

From an industrial perspective, the durable structure of lobe pumps provides reliability even under challenging conditions such as aggressive chemicals, sticky products, or high temperatures. Heated jacket models allow the product to remain at a constant temperature, enabling the seamless transfer of viscous fluids. Quiet operation, low vibration, and energy efficiency are additional advantages that contribute to operational efficiency.

In conclusion, lobe pumps are not just a pump but also a strategic investment in terms of efficiency, hygiene, and durability. Whether maintaining quality in food production, ensuring safety in chemical processes, or increasing efficiency in textiles or transportation, lobe pumps offer reliable solutions in every sector. The high-quality lobe pumps developed by MIT and INOXEN brands have taken these advantages a step further, making them among the most preferred fluid transfer equipment in modern industrial processes.