In industrial facilities, energy efficiency, process safety, and operational stability are directly related not only to the workforce or automation but also to the technical competence of the equipment used and its compatibility with the system. Auxiliary systems on the production line, such as blower systems used in air transfer, vacuum, drying, or ventilation applications, are among the most critical components affecting efficiency.

Proper management of air flow directly affects many technical and operational variables, from the uninterrupted operation of the production line to the extension of machine life, the stability of environmental parameters, and the quality of the final product. Incorrectly selected or insufficient capacity blower systems can lead to irregularities in production processes, energy waste, excessive maintenance needs, and ultimately high operating costs.

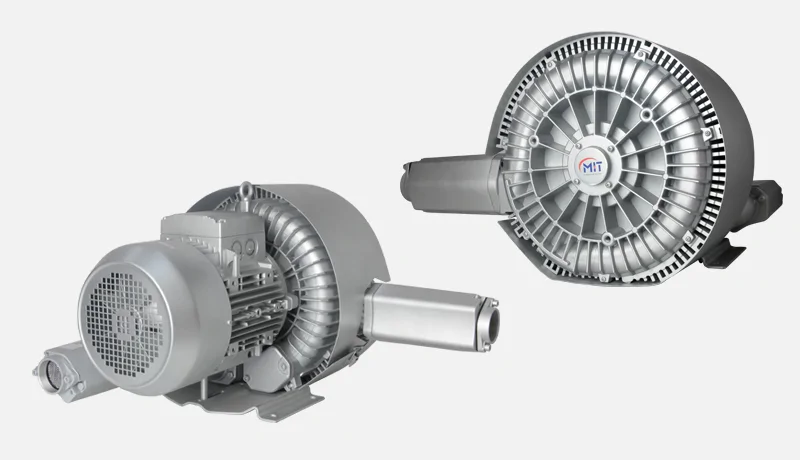

At this point, MIT centrifugal blower systems offer powerful, optimized, and reliable solutions that make a difference in industrial air management, supporting both the performance and sustainability of facilities. With its high-efficiency fan structure, it maintains maximum air flow while increasing comfort and safety in the operating environment with its quiet AC motor technology. Additionally, Swedish SFK or Japanese NSK bearings minimize the maintenance needs of the system while providing long-term and stable operational performance.

MIT blowers not only transport air but also save energy in the production environment, reduce noise pollution, balance the load on mechanical systems, and contribute to the creation of an environmentally friendly production model. With these features, they become an effective part of the business's energy efficiency strategy and process control policies, not just a technical device.

Moreover, MIT blower systems are produced in a modular and scalable manner to adapt to the variable process requirements of different sectors. Whether in a low-pressure filling line or a treatment facility with high flow needs, it offers specially optimized models for each application. With a wide range of models, alternatives suitable for every need have been developed with flow capacities ranging from 40 m³/h to 2500 m³/h and pressure values reaching up to 670 mbar.

This versatile structure provides great advantages for facility managers and maintenance teams. Because these systems not only technically align with the process but also offer operational contributions such as reduced failure risk, low spare parts need, and easy installation. Especially in sectors with high downtime costs or working in multiple shifts, the stability provided by MIT blower systems directly translates into time and cost savings.

In short, MIT centrifugal blower systems are not just a fan device; they are a strategic investment that supports production lines, optimizes energy consumption, minimizes failures, and maximizes efficiency. For every business that wants to create sustainable, smart, and future-oriented production models, MIT blowers are the right choice both technically and financially.

Blowers are high-efficiency fan systems used to transport, compress, or circulate air or gas in a specific direction and pressure. These devices serve many different processes by moving the air they suck from the environment at specified flow (m³/h) and pressure values (mbar/bar). Blowers, generally preferred in systems requiring low and medium pressure air flow, play a critical role in increasing production efficiency and ensuring process continuity.

Centrifugal blowers operate with the centrifugal (centripetal) effect of the wheels in their internal structures. As the wheel rotates, it pushes the air outward in a spiral motion thanks to the blade structure. The vortex movements formed at this time change both the direction and pressure of the air. The air is sucked from the inside by the rotation of the wheel and pressurized outward, thus progressing through the system by compressing. Thanks to this principle, blowers provide a stable and balanced air flow, allowing processes to continue without interruption.

Blowers not only transport air; they also pressurize, direct, and keep it under control in a way suitable for the process. In this way, they perform different tasks in many industries. For example, while performing air spraying duties in product washing and drying lines, they provide vacuum power in dust extraction systems; while blowing clean air in bottling machines, they work as material directors in paper processing lines.

Additionally, blower systems stand out for being compact, lightweight, low-noise, energy-efficient, and environmentally friendly due to their structures. Thanks to these features, they provide the performance needed by production facilities while also offering the advantage of low operating costs and high reliability.

Especially MIT centrifugal blower systems stand out with their superior engineering structure in these areas. With high-efficiency fan design, quiet and maintenance-free motor systems, high-quality bearing components, and environmentally sensitive operating principles, MIT blowers are not only an air transport device but also a technological investment that creates value in terms of energy management, process safety, and operational sustainability.

Key Features of MIT Blower Systems

MIT branded centrifugal blower systems offer distinct advantages over their competitors in terms of high efficiency, long life, low maintenance needs, and environmental sustainability in industrial air management. Designed with an advanced engineering approach, these blowers have become a reliable solution partner in the production processes of businesses with both technical performance and user-friendly structure. Below, you can examine in detail the main features that highlight MIT blower systems:

• High-Efficiency Fan Design

The fan system at the heart of MIT blowers is specially designed to provide maximum air flow. Thanks to aerodynamically optimized fan blades, air flow is directed without loss and in a balanced manner. This means more air is transported with less energy. This efficiency significantly reduces energy costs, especially in continuously operating processes.

• Low Energy Consumption and Quiet Operation

The high-efficiency AC electric motors used in blower systems provide long-term and economical use with low power consumption. Additionally, thanks to the internal structure of the motor and system insulation, the noise level generated during operation is kept to a minimum. This provides an ideal environment in terms of both work safety and user comfort. The noise level generally ranges between 50–85 dBA, and it does not cause discomfort even in intensive production areas.

• Superior Bearing Quality for Long Life

Swedish SFK or Japanese NSK bearings are used in MIT blower systems. These high-quality bearings minimize wear due to friction, ensuring that the blower operates long-lasting and maintenance-free. This structure, which can work safely without requiring service for 3 to 5 years, significantly reduces maintenance costs and downtime for businesses.

• Oil-Free Operation Principle: Environmentally Friendly and Clean Air

MIT blowers operate on a completely oil-free principle. This feature not only offers an environmentally friendly solution but also allows it to be used safely in sectors requiring high sensitivity in air quality (such as food, medical, chemical). Since there is no risk of leakage in oil-free systems, product and process safety is maximized.

• Dynamic Balance Adjustment for Minimum Vibration

System components undergo precise balance adjustments during the production phase. This minimizes the vibration generated by the fan and motor systems during operation. Reducing vibration increases the overall durability of the blower and prevents it from negatively affecting the equipment around it. Additionally, low vibration supports quiet operation performance.

• Flexible Installation: Horizontal and Vertical Setup Possibility

MIT blowers are designed to be mounted both horizontally and vertically to adapt to different production areas. This flexibility allows installation even in narrow spaces and overcomes architectural constraints during the project planning process. Thanks to its compact structure, it can be easily integrated into different points such as under panels, on machines, or along walls.

Usage Areas: In Which Sectors are MIT Blowers Used?

Centrifugal blowers play a critical role in many stages of modern industrial production. Blowers are used as one of the main equipment in all processes requiring controlled and efficient transfer of air or gas. MIT branded blower systems are safely preferred in many sectors thanks to their robust engineering, high performance values, and environmentally friendly design.

Here are the main sectors and application areas where MIT blowers are intensively used:

• Food Industry

The food sector is one of the areas where hygiene, air quality, and process sensitivity must be kept at the highest level. At this point, MIT blowers are safely used in many applications from vegetable and fruit washing systems to bottle drying units, filling machines to vacuum transport systems. Thanks to the oil-free operating principle, it works without creating air pollution in environments where there is a risk of contact with food.

• Plastic, Granule, and Powder Transfer Systems

High-flow air flow is needed for the safe and fast transport of thermoplastic raw materials, granules, or powder products along the production line. MIT blowers allow the product to be conveyed both without damage and in an energy-efficient manner in dust granule carriers and pneumatic transfer lines.

• Industrial Dust Collection and Gas Removal

The removal of harmful gases and dust particles formed in industrial facilities from the environment is mandatory for both employee health and environmental sustainability. MIT blower systems offer an effective solution with strong suction capability in filtered dust collection units, gas extraction systems, and vacuum cleaning equipment.

• Paper and Printing Industry

In paper processing processes, precise air control is needed at points such as static electricity discharge, paper transport, cutting, and printing stages. MIT blowers prevent paper deformation and increase print quality by working at high speed and low vibration in such applications.

• Automotive Industry

Strong air flow is needed in areas such as automatic vehicle washing machines, tunnel-type drying systems, and pre-paint surface cleaning applications. MIT blowers offer high performance in such applications thanks to their compact structure and high pressure capacity. Additionally, they provide a comfortable working environment with low noise levels.

• Water Treatment Plants and Jacuzzi Systems

Blower systems undertake the task of aeration in biological treatment processes. Transferring sufficient oxygen to pools or tanks is vital for the survival of microorganisms and the decomposition of waste. MIT blowers are a reliable part of treatment systems with strong air distribution, energy efficiency, and continuous operation capability. Similarly, they are used to create air bubbles in jacuzzi and spa systems.

• HVAC Systems and Heating Installations

In the climate control and heating systems of buildings, blowers that provide air circulation are essential elements. MIT blowers stand out with low energy consumption and long life advantage in applications such as fresh air intake and exhaust, in-duct air movement, and heat recovery systems in HVAC systems. They can also be used in tasks such as combustion air supply or flue gas extraction in heating systems.

Considerations in Blower Selection

Blower systems are of critical importance for the efficient, safe, and sustainable operation of production processes. However, the air flow, pressure level, environmental conditions, and performance expectations of each application are different. Therefore, blower selection should be made based on detailed engineering criteria, not just motor power or appearance. An incorrectly selected blower can lead to process disruptions, energy waste, equipment failures, and increasing maintenance costs over time.

Below are the main factors to consider in detail when determining the most suitable MIT blower model for your application:

• Required Air Flow (m³/h)

The amount of air needed for each process is different. The air flow (flow rate) required for each application, from washing systems to granule transfer, from gas removal to ventilation, should be determined, and the blower should be selected with a capacity suitable for this need. A very low-capacity blower can cause the process to slow down or become inefficient, while an overly powerful system can create unnecessary energy consumption and excessive noise.

• Positive Pressure or Vacuum?

Some blower systems are preferred for providing positive pressure (air push), while others are preferred for vacuum (air suction). For example, bottle drying machines need positive air pressure, while dust extraction systems work with vacuum effect. Therefore, it should be determined whether your system needs an air-blowing or air-sucking structure, and the blower selection should be made accordingly.

• Ambient Temperature and Physical Conditions

Factors such as the temperature value, humidity level, dust load, and chemical contents of the environment where the blower will operate directly affect the product life and performance. For example, in systems operating at high temperatures, the blower must be resistant to this temperature. MIT blowers offer resistance up to 130°C, allowing them to work smoothly even in such challenging conditions. Additionally, installations supported by filter systems prevent the fans inside the blower from being affected by dust.

• Energy Efficiency and Noise Level

Low energy consumption in industrial systems provides a great advantage in reducing operating costs. In addition, the noise level of blowers operating in closed areas where personnel are constantly present is important. MIT blowers offer ideal performance in these criteria with both high efficiency and a quiet operating range of 50–85 dBA.

• Installation Flexibility and Space Suitability

The size, shape, and position of the area where installation will be made require flexibility in blower selection. MIT blowers can be mounted both horizontally and vertically. This allows easy integration into narrow spaces, on top of machines, or in special system boxes. Thanks to its compact design, it easily adapts to both new projects and existing systems.

MIT branded blower systems offer a wide product range that can meet all these criteria with air flow options ranging from 40 m³/h to 2500 m³/h and pressure capacities reaching up to 0–670 mbar. Whether it's a low-flow laboratory application or a production line requiring high pressure — MIT blowers are designed to provide the right solution tailored to your needs.

Single and Double Stage Blower Options

• Single Stage Blowers: 40–1370 m³/h flow and 0–460 mbar pressure range

• Double Stage Blowers: 88–2500 m³/h flow and 0–670 mbar pressure range

Both models are produced based on energy efficiency, quietness, and long life.

Considerations in Blower Usage

Blower systems offer long-lasting, efficient, and trouble-free performance when used under the right conditions and appropriately. However, many usage errors that shorten the system's life, increase energy consumption, and pose a risk to work safety are frequently encountered in the field. Therefore, paying attention to some technical rules during the installation and operation of blower systems is of great importance. Below are the main considerations to be aware of when using all blower systems, especially MIT centrifugal blowers:

• Suction and Discharge Points Should Be Continuously Checked for Blockages

The inlet (suction) and outlet (discharge) points of the blower system can become blocked over time due to dust, granules, particles, oil vapor, or foreign objects. This situation hinders air flow, reducing the system's performance and causing the motor to be excessively strained. Therefore, it is recommended to periodically check, clean, and support blower lines with replaceable filters when necessary. Additionally, the use of a safety valve to protect the system in cases of excessive pressure or vacuum is a vital safety measure for both the blower and the surrounding equipment.

• Motor Rotation Direction Should Be Installed Correctly

The fan inside blower systems is designed to rotate in a specific direction. If the motor is connected in reverse during installation, the fan will rotate in the opposite direction, preventing the air from being directed to the outlet. Blowers operating in reverse not only cause efficiency loss but also lead to unbalanced load distribution and early wear in internal mechanical parts. Therefore, the motor's rotation direction should always be checked before the first operation. MIT blowers are provided with direction markings and rotating fan indicators to facilitate this check.

• Filter Usage Should Not Be Neglected

Contaminants such as dust, sand, metal particles, and oil vapor entering the blower with air cause wear, imbalance, and balance disruptions, especially in fan blades and bearing seats. This gradually reduces the blower's performance and results in more frequent maintenance needs. Therefore, an air filter with a suitable mesh size should be added to the blower's suction line, and filters should be regularly cleaned or replaced. Additionally, not using a filter can increase the release of harmful particles into the environment, resulting in a situation contrary to environmental regulations.

All these precautions not only prevent the blower system from malfunctioning but also provide great advantages in terms of energy efficiency, system stability, and operational safety. Especially since MIT blowers are developed considering such critical issues, they provide both economic and technical benefits to businesses in the long run.

Why MIT Blower?

When it comes to industrial air management solutions, choosing the right equipment is not just a technical decision; it is also a strategic investment in terms of efficiency, sustainability, and operational safety. At this point, MIT branded centrifugal blowers have become a reliable choice both in Turkey and in the international market with their high-tech engineering approach, long-lasting component usage, and performance-oriented production processes.

• Production Equipped with High Technology

MIT blowers are designed using advanced analysis and simulation techniques in R&D and engineering processes. Each product is subjected to air flow optimization, thermal durability, and mechanical vibration tests before being launched. This provides not only a powerful but also a precise and balanced air management solution.

• Long-Term Performance and Reliability

MIT blower systems are equipped with superior components such as Swedish SFK and Japanese NSK bearings, high-efficiency AC motors, and balanced fan designs. Thanks to this structure, blowers can generally operate continuously without requiring maintenance for 3 to 5 years, minimizing production losses due to system downtimes.

• Energy Efficiency and Quiet Operation

Since centrifugal blowers operate in industrial environments where energy consumption is intense, MIT blower systems are specifically designed to provide low energy consumption. This offers an advantage in terms of environmental sustainability and reduces operating costs. Additionally, thanks to the low noise level motor and fan structure, it provides a quiet and comfortable working environment.

• Easy Installation, Integrable Design

MIT blowers can be seamlessly integrated into different production areas thanks to their compact body structure suitable for both horizontal and vertical mounting. Additionally, the lightweight body structure, ergonomic connection points, and simple control panel make the installation process extremely fast and practical. These features not only save time but also significantly shorten the system commissioning time.

• Global and Local Compliance

MIT blower systems are produced in compliance with both local regulations and international standards. This allows them to be safely used not only in production facilities in Turkey but also in the European, Middle Eastern, and Asian markets. Offering solutions tailored to different needs for OEM manufacturers, machine integrators, and end-users is also among MIT's flexible production capabilities.

Conclusion: Quieter, More Efficient, More Powerful

Whether you want to ensure hygienic air flow in food processing processes, control dust and gas transfer in the chemical and plastic industries, or create uninterrupted air circulation in an industrial line with a high production pace — MIT centrifugal blower solutions offer a reliable, long-lasting, and high-performance solution for air management for businesses of all sizes.

Going beyond the basic functions expected from blower systems; MIT blowers, which make a difference in many areas such as high flow capacity, maintenance-free structure, quiet operation, environmentally friendly design, and energy efficiency, perfectly respond to both today's and future needs of industrial facilities.

If you are aware of the loss that a stoppage in your production line can create, the reliability of the equipment you use for the continuity of your processes is of critical importance to you. MIT blowers provide this confidence with their durable structure that can operate without requiring maintenance for 3 to 5 years. Additionally, the balanced fan structure and efficient motor systems, produced with high engineering precision, reduce both energy consumption and minimize noise and vibration that may occur in the working environment.

Offering easy installation possibilities with a design suitable for horizontal and vertical installation, MIT blowers can be integrated into both new systems and existing production lines, providing flexibility and time savings in engineering projects. Its compact structure saves space in applications in different sectors, while not compromising high performance standards.

Moreover, MIT blowers stand out not only with their technical features but also with their expert engineering support, fast spare parts supply, and customer satisfaction-focused approach after sales. You are not left alone after purchasing the product; you experience the advantage of progressing with a strong solution partner. This provides long-term confidence and stability in your investment decisions.

Additionally, for businesses adopting an environmentally conscious production philosophy, the oil-free operation principle and low carbon footprint motor structure of MIT blowers directly contribute to sustainability policies. With a system that has low energy consumption, minimum maintenance cost, and long life, you not only gain operational advantage but also fulfill your environmental responsibilities.

In conclusion, whether used in an automation system, a packaging line, or a treatment facility — MIT blower systems are the ideal choice for increasing your business's efficiency, reducing maintenance costs, and creating a sustainable production environment. These systems are a solid engineering investment that will respond to not only today's but also future production needs.

Before deciding on the right blower system for your business, be sure to evaluate MIT solutions. By contacting our expert team, you can plan the most efficient solution tailored to your needs together and take your business's air management performance to the next level. With our strong technical infrastructure, high production quality, and industry experience, we offer you not just a product but a long-term solution partnership.