One of the most important ways to achieve efficiency, continuity, and reliability in heating-cooling systems is the harmonious operation of equipment. At this point, plate heat exchangers and accumulation tanks stand out as two critical pieces of equipment that complement each other. While the exchanger provides heat transfer between different circuits, the accumulation tank stores this energy, enabling stability and continuity in the system.

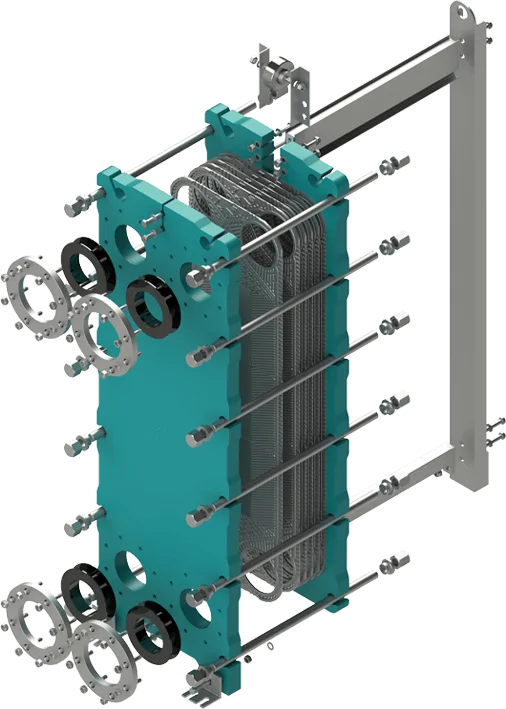

The plate exchanger essentially allows two different fluids to transfer heat without mixing. For example, it safely transfers hot water from sources such as boilers, heat pumps, or solar energy to the domestic water or heating line. However, this energy may not always be used simultaneously with demand. This is where the accumulation tank comes into play. By storing the hot water passing through the exchanger, the tank becomes a ready energy source during peak demand. Thus, the system is protected from fluctuations, and the energy source does not unnecessarily turn on and off.

This collaboration provides great advantages, especially in hotels, hospitals, factories, and large residential projects where usage is intense. While the accumulation tank acts as a buffer to meet sudden hot water or heating demands, the plate exchanger ensures controlled and safe energy transfer. As a result, the system operates more balanced, with a longer lifespan and higher efficiency.

Moreover, this harmony is valid not only for heating but also for cooling applications. In chiller systems, while the cooled water is transferred to the consumption line via the exchanger, the accumulation tank stores the cold energy, preventing the system from being strained during peak demands. This ensures energy savings and prevents users from experiencing a loss of comfort.

In summary, the collaboration between the plate exchanger and the accumulation tank creates an intelligent structure that separates the source from consumption, stores energy, and balances the system. Thanks to this structure, energy is used more efficiently, operating costs decrease, and system reliability increases.

For a heating-cooling system to work efficiently and have a long lifespan, it is not enough to have powerful equipment; this equipment must also work in hydraulic balance. The harmony between plate exchangers and accumulation tanks comes into play precisely at this point.

Plate exchangers safely and efficiently perform heat transfer by separating different circuits. Thus, primary source circuits such as boilers or heat pumps are connected to secondary circuits such as domestic water or heating lines without direct contact. Here, the accumulation tank acts as a balancing reservoir. It receives energy from the exchanger, stores it, and transfers it to the system in a controlled manner according to demand. Thus, continuous harmony is ensured between the primary (source) and secondary (consumption) circuits.

This partnership offers great advantages in terms of hydraulic balance. The accumulation tank absorbs sudden flow and pressure changes that may occur in the system. Thus, pumps are not unnecessarily strained, pressure fluctuations on the pipe installation are reduced, and the lifespan of the equipment is extended. At the same time, the exchanger balances the different flow and temperature conditions of the fluid in both circuits, allowing energy to be transferred without loss.

Flow management is also an important part of this collaboration. Especially in large-scale facilities, demand constantly varies. For example, in a hotel, hot water usage is at its highest in the morning and drops to a minimum at midnight. The accumulation tank softens this variable demand; the exchanger continuously transfers energy from the source with constant efficiency. Thus, both comfort is maintained, and energy consumption becomes balanced.

In conclusion, the plate exchanger-accumulation tank combination is critical not only for heat transfer but also for the hydraulic stability and flow management of the system. This harmony is one of the most reliable solutions that increase both technical performance and operational efficiency in installations.

Complementing Each Other in Terms of Capacity and Scalability

One of the most important expectations in modern installation systems is scalability and capacity flexibility according to need. Because energy demand is not constant; it varies according to the time of day, season, user density, or the state of the industrial process. At this point, the collaboration of plate exchangers and accumulation tanks allows the system to adapt to every condition.

Plate exchangers are quite flexible in terms of capacity increase or decrease due to their modular structures. The heat transfer capacity of the exchanger can be increased by adding more plates; it can also operate at lower loads by removing plates. This feature allows a single device type to be adapted to a wide variety of needs in different projects.

However, increasing only the capacity of the exchanger is not sufficient on its own. Because energy demand can increase instantly, and the heat transferred by the exchanger may not be immediately consumed. In this case, the accumulation tank comes into play, storing excess energy and returning it to the system when needed. Thus, the system becomes more resilient to demand fluctuations.

For example, in a hotel, the need for hot water increases rapidly during peak usage hours in the morning. While the exchanger continuously provides heat transfer, the energy previously stored in the accumulation tank meets this demand. Similarly, in industrial facilities, there may be an instantaneous high-temperature need at different stages of the process; the tank meets this load, allowing the exchanger to operate steadily and balanced.

Thus, the plate exchanger is responsible for instantaneous and continuous energy transfer, while the accumulation tank operates on the store-transfer principle. Thanks to this dual structure, the system's capacity is managed flexibly according to actual needs. In other words, scalable solutions are created with the same principles everywhere, from small-scale residential projects to large industrial facilities.

In conclusion, the plate exchanger and accumulation tank are two powerful players that complement each other in capacity management. This harmony offers businesses a flexible, reliable, and economically sustainable solution in the long term.

Contribution to Energy Efficiency and Sustainability

Today, as energy costs continue to rise, environmental concerns have also become a priority for businesses. Therefore, in every new installation system, not only technical performance but also energy efficiency and sustainability are prioritized. The duo of plate exchangers and accumulation tanks is one of the most effective solutions to achieve these goals.

Plate exchangers offer high heat transfer efficiency thanks to thin metal plates. The turbulent circulation of fluids allows maximum heat exchange with minimal energy. This means much lower energy losses, especially compared to traditional tubular exchangers. Efficient use of energy reduces both operating costs and carbon footprint.

The accumulation tank is the second important element supporting this efficiency. The tank balances the heat or cooling energy demanded by the system according to instantaneous fluctuations. Thus, the energy source (e.g., boiler or heat pump) does not constantly turn on and off; it operates more stably and with less energy consumption. This situation extends the device's lifespan and prevents unnecessary energy expenditure.

Additionally, this combination offers great advantages for energy recovery. Waste heat released in industrial facilities can be transferred to another circuit via plate exchangers and stored in the accumulation tank for reuse. For example, waste heat generated in a production line can be used for hot water production or heating purposes. Thus, the energy cycle is closed, and direct contributions are made to sustainability goals.

Environmental benefits cannot be ignored either. Efficient use of energy reduces fossil fuel consumption, which directly means a decrease in greenhouse gas emissions. Especially in projects aiming for green building certification such as LEED or BREEAM, the integration of plate exchangers and accumulation tanks fulfills an important criterion.

In conclusion, the combination of these two pieces of equipment not only reduces operating costs but also provides environmentally friendly and sustainable energy management. Therefore, in today's modern installation solutions, plate exchangers and accumulation tanks are considered among the most reliable partners for efficiency and sustainability.

Effects on Comfort and System Stability

In a heating-cooling system, it is not enough to only produce energy; delivering this energy to the user comfortably and stably is as important as energy efficiency. The harmony between the plate exchanger and the accumulation tank plays a critical role in establishing this balance in systems.

The plate exchanger performs heat transfer safely and quickly by separating different circuits. Thus, the energy coming from the source is controlled before being directly transferred to the user circuit. However, energy demand is not always constant; in the morning, the need for hot water in a hotel is at its peak, while at midnight, it is at its minimum. At this point, the accumulation tank comes into play to maintain comfort.

The tank acts as a buffer in the system by storing the energy coming from the exchanger. Energy is stored when demand is low; when demand suddenly rises, this energy is quickly activated. Thus, temperature fluctuations are not experienced on the user side, and comfort is continuously maintained.

This partnership also provides great advantages in terms of system stability. The accumulation tank absorbs sudden pressure and flow changes, preventing pumps, pipelines, and other equipment from being strained. Thus, the system operates more quietly, without vibration, and balanced. Additionally, since the exchanger balances the temperature differences between different circuits, heat losses decrease, and the overall stability of the system increases.

For example, in a central heating system, sudden loads can cause users to encounter very hot water in some places and insufficiently heated water in others. The plate exchanger-accumulation tank combination eliminates these imbalances, providing homogeneous temperature distribution at every point. The same applies to cooling systems; thanks to the tank, the temperature of the cooled water remains constant, ensuring comfortable indoor climate control.

In conclusion, the harmony between the plate exchanger and the accumulation tank not only increases energy efficiency but also guarantees user comfort. This duo is a powerful solution that ensures the system remains technically stable and the end-user experience is at the highest level.

Integration with Different Energy Sources (Boiler, Heat Pump, Solar Energy)

In modern installation systems, instead of relying on a single energy source, the use of different sources together is becoming increasingly common. The main reason for this is to reduce energy costs and increase sustainability. The plate exchanger and accumulation tank play a key role in this multi-source integration.

Boiler Systems:

Hot water or steam obtained from boilers is usually produced at high temperatures and certain pressures. Directly supplying this energy to the consumption circuit is not safe. The plate exchanger creates a safe bridge by separating the boiler circuit from the consumption circuit. The accumulation tank stores this energy, preventing the boilers from frequently turning on and off. Thus, fuel savings are achieved, and the boiler's lifespan is extended.

Heat Pumps:

Heat pumps are highly energy-efficient devices, but their operating characteristics are sensitive to fluctuations. When demand suddenly rises, it can be difficult for the heat pump to meet this load alone. The plate exchanger protects the heat pump circuit, while the accumulation tank plays a balancing role by supplying the stored energy to the system. Thus, the heat pump operates more stably and efficiently without constant modulation.

Solar Energy Systems:

The temperature obtained from solar energy varies depending on the time of day and weather conditions. Therefore, it is often not sufficient to connect it directly to the consumption circuit. The plate exchanger separates the fluid coming from the solar collectors from the main system, and the accumulation tank stores this energy and transfers it to the system when needed. Thus, energy obtained from the sun is used efficiently even on cloudy days or at night.

Multi-Source Compatibility:

In some large-scale projects, boilers, heat pumps, and solar energy are included in the same system. In this scenario, plate exchangers safely separate the circuits, while accumulation tanks collect energy from all sources and make it available according to demand. This combination reduces costs and supports environmental sustainability.

In conclusion, the plate exchanger and accumulation tank facilitate the integration of different energy sources into the system, providing flexibility, safety, and maximum efficiency. This ensures that systems are compatible with both today's and future energy solutions.

Application Areas: Residential, Industrial Facilities, and Commercial Buildings

The combination of plate exchangers and accumulation tanks is not only a technical solution but also a versatile application tool that finds its place in different sectors. The joint use of these two pieces of equipment provides high efficiency and reliability in both small-scale residences and large-scale industrial facilities.

Residential Projects:

In collective living spaces, apartments, or villas, hot water comfort is of great importance. Especially in the morning and evening, sudden consumption increases occur. While the plate exchanger safely transfers energy from the boiler or solar energy system to the domestic water, the accumulation tank stores this energy, acting as a buffer against fluctuations. Thus, users always have access to water at a constant temperature. At the same time, unnecessary activation of energy sources is prevented, reducing operating costs.

Industrial Facilities:

In factories, production processes often require different heat levels. Instant high-temperature demands are frequently seen in sectors such as textiles, food, chemicals, or metal processing. The plate exchanger safely provides the necessary temperature level by isolating the process water from the source. The accumulation tank meets the energy demand during intense process moments. Thus, there are no interruptions in production lines, and processes continue uninterrupted. This duo is also frequently preferred for waste heat recovery.

Commercial Buildings:

In buildings such as hotels, hospitals, shopping centers, and office buildings, energy demand varies throughout the day. For example, in a hotel, hot water usage peaks in the morning and drops to almost zero at night. While the accumulation tank balances these fluctuations, the plate exchanger transfers energy from the source to the consumption circuit in a controlled manner. Thus, both comfort is maintained, and energy consumption is optimized. In critical buildings like hospitals, system reliability is prioritized; this duo structure ensures uninterrupted hot water and heating.

In conclusion, the plate exchanger-accumulation tank combination guarantees comfort in residences, efficiency in industrial facilities, and continuity in commercial buildings. This wide range of applications is the clearest indicator that the system is a flexible, reliable, and universal solution.

The Importance of Harmony in Material and Design

In systems where plate exchangers and accumulation tanks work together, not only capacity or energy efficiency but also material selection and design harmony are critical factors. Because even the smallest mismatch between these two pieces of equipment can reduce system performance, increase maintenance needs, or shorten lifespan.

Material Selection in Plate Exchangers:

Exchanger plates are usually made of stainless steel. However, titanium or nickel alloys are preferred in some applications where high corrosion resistance is required. Gasket materials are also determined according to the temperature and chemical structure of the fluid. If the correct selection is not made here, plates may wear out quickly or sealing problems may occur.

Material Preference in Accumulation Tanks:

Tank bodies are generally made of carbon steel, but enamel coating or stainless steel solutions are also widely used against corrosion. Especially in domestic water applications, hygiene is of great importance, so enamel coating and cathodic protection (such as magnesium anode) are preferred. In industrial processes, high temperature and pressure-resistant, if necessary, stainless steel bodies are selected.

Design Harmony:

The connections between the exchanger and the tank must be correctly sized. Incorrect diameter piping or insufficient insulation can lead to significant energy losses in the system. Additionally, the internal design of the tank plays a critical role. In tanks designed according to the stratification (layering of hot water on top and cold water below) principle, energy from the exchanger is stored more effectively.

Harmony in Terms of Hygiene and Safety:

In systems used in the food, pharmaceutical, and healthcare sectors, both the exchanger and the tank must comply with hygienic design standards. At this point, surface smoothness, easy cleanability, and compatibility with CIP (cleaning in place) systems come to the fore.

Harmony for Long-Lasting Use:

If the correct choices are not made in material and design, the system's maintenance needs increase, energy efficiency decreases, and the investment cost may be wasted in a short time. However, with compatible selections, both the plate exchanger and the accumulation tank work smoothly for many years, reducing the total operating cost.

In short, not only working together but also supporting with compatible material and design features is one of the most important criteria that directly determine system performance and reliability.

Ease of Maintenance and Operational Continuity

One of the most important factors determining the lifespan of a heating-cooling system is the ease of maintenance processes and the uninterrupted operability of the system. The harmony of the plate exchanger and accumulation tank offers significant advantages to users in this regard.

Ease of Maintenance in Plate Exchangers:

One of the biggest advantages of plate exchangers is their removable and replaceable plates. Thanks to this feature, exchangers can be easily cleaned, and plate changes can be made quickly. Especially in systems where scaling or sediment formation is observed, maintenance time is minimized. Additionally, when used with CIP (cleaning in place) systems, chemical cleaning can be performed without the need to disassemble the exchanger. This contributes to less downtime and the preservation of operational continuity.

Maintenance in Accumulation Tanks:

Since accumulation tanks do not contain moving parts, maintenance requirements are quite low. The most important issues to pay attention to in tanks are corrosion and hygiene. These risks are minimized thanks to enamel coating, stainless steel body, and anode rods. Regular anode checks and replacements when necessary ensure the tank operates long-term. Additionally, the insulation quality of the tanks should be periodically checked; because when insulation weakens, energy losses increase.

System Continuity:

The joint operation of the plate exchanger and accumulation tank ensures that the system does not completely go offline even during maintenance. For example, thanks to the energy stored in the tank, the system can continue to serve the user during short-term exchanger maintenance. This feature provides a great advantage, especially in buildings with uninterrupted energy needs such as hospitals, hotels, or industrial facilities.

Cost Advantage:

The ease of performing maintenance operations directly affects not only continuity but also costs. Thanks to less labor, shorter maintenance times, and lower spare part needs, operating costs decrease in the long term.

In conclusion, the combination of the plate exchanger and accumulation tank offers an economic and safe solution to the user by providing not only efficiency but also easy maintenance and high operational continuity.

Environmental and Economic Gains

The joint use of plate exchangers and accumulation tanks provides significant contributions not only in terms of technical performance and comfort but also in terms of environmental benefits and economic gains. The harmony of these two pieces of equipment helps businesses reduce their costs and achieve sustainability goals.

Reduction in Energy Consumption:

The plate exchanger provides maximum heating or cooling performance with minimal energy thanks to its high heat transfer efficiency. The accumulation tank transfers the stored energy to the system during demand, preventing the energy source from constantly operating. Thus, energy-consuming devices such as boilers, heat pumps, or chillers are activated less frequently, reducing total energy consumption.

Savings in Operating Costs:

The reduction in energy consumption directly means savings in fuel, electricity, and maintenance expenses. Additionally, less strain on devices reduces the risk of malfunctions, lowering spare part and service costs. In the long term, this accelerates the return on investment.

Environmental Sustainability:

More efficient use of energy reduces fossil fuel consumption, leading to a decrease in carbon emissions. This is an important contribution, especially for businesses aiming to reduce their carbon footprint. Additionally, thanks to the accumulation tank, energy obtained from renewable sources such as solar energy can be stored and used more effectively. This situation is a critical advantage in environmentally friendly projects.

Contribution to Green Building Certifications:

International green building certifications such as LEED and BREEAM consider energy efficiency and environmental performance criteria. The integration of plate exchangers and accumulation tanks supports these criteria in terms of energy recovery and sustainable use, increasing the certification scores of projects.

Long-Term Economic Value:

When looking at the initial investment cost, the exchanger and tank combination may seem like an additional cost. However, in the long term, its low operating expenses, energy savings, and long device lifespan significantly reduce the total cost of ownership. This provides a great economic advantage for both businesses and individual users.

In conclusion, the harmony of plate exchangers and accumulation tanks is an intelligent investment that supports not only today's needs but also the environmentally friendly and economic systems of the future.

Conclusion

Plate exchangers and accumulation tanks are two strategic pieces of equipment that complement each other in modern heating-cooling systems. While exchangers provide safe and efficient heat transfer between different circuits, accumulation tanks store energy, maintaining the continuity and balance of the system. This ensures both comfort and system stability.

The harmony of the two pieces of equipment not only increases energy efficiency but also reduces operating costs, extends device lifespan, and directly contributes to environmental sustainability. The ability to integrate with different energy sources makes this structure flexible and future-proof, offering a wide range of applications from residential to commercial buildings, industrial facilities to renewable energy projects.

In conclusion, the plate exchanger-accumulation tank combination has become an indispensable choice for every business and structure seeking high efficiency, low cost, environmentally friendly solutions, and long-term reliability. When supported with the right material selection, appropriate design, and regular maintenance, this harmony continues to work seamlessly for many years, adding value to both the user and the environment.