Lobe pumps are designed as an advanced member of the valveless and positive displacement pump family. Unlike traditional centrifugal pumps, this system operates by rotating each rotor within a mutually geared box, based on the principle of volumetric displacement. As the rotor lobes approach each other, they create an intake chamber that draws fluid into the pump body. When the lobes separate, a closed volume is formed, and the fluid is conveyed to the outlet point as it progresses within the body. This cycle minimizes variations in flow rate and backflow, maintaining a constant volume with each revolution; as a result, operational reliability and process control are significantly enhanced.

Rotor geometry forms the heart of lobe pump performance. Two, three, or butterfly-shaped lobe configurations are selected based on viscosity, particle size, and flow rate requirements. Two-lobe models are generally preferred for high efficiency and low-pressure applications, while three-lobe versions offer a more stable flow profile. Butterfly rotor designs create low shear effects and provide superior durability in pressurized processes, especially in low-thickness and thin-film transmissions. The CAD-supported precision machining of the lobes allows for micron-level control of tolerances within the pump, minimizing the risk of clogging and wear even with high-viscosity or particle-laden fluids.

Another important advantage of the positive displacement principle is the self-priming capability of these pumps. Even in air-locked lines, the pump quickly vacuums the pipeline connected to the sip sap, initiating fluid flow without the need for an additional primer or auxiliary pump. Additionally, the frictionless contact rotor-wheel-less design guarantees the preservation of product quality and molecular structure during the transfer of solutions requiring high hygiene and precision. This feature is of critical importance, especially in the food, pharmaceutical, and cosmetic industries.

The valveless design of lobe pumps also simplifies maintenance and cleaning processes. The design, which leaves no dead volume within the body for CIP (Clean-In-Place) and SIP (Sterilize-In-Place) applications, ensures that chemical cleaning solutions and steam reach every point. Mechanical seals and flushed cartridge systems maintain safe operation in challenging environments such as high-sugar jams or dense ester solutions. Therefore, lobe pumps continue to be an indispensable technology for industrial fluid transfer, offering longevity, low maintenance costs, and continuous operation advantages.

The most critical issue in equipment selection in the food and beverage sector is that the contact surfaces are made of food-grade materials approved by the FDA (Food and Drug Administration). In MIT Lobe Pumps, all parts in contact with the fluid are manufactured from AISI 316L stainless steel of 1.4404 quality. This alloy offers superior resistance to corrosion due to its high chromium and molybdenum content, while its hard and smooth structure minimizes the risk of bacterial adhesion. The internal surfaces are polished to a Ra ≤ 0.8 µm level or electropolished to create a microscopically smooth structure. This ensures that during both CIP (Clean-In-Place) and SIP (Sterilize-In-Place), cleaning fluids can easily remove dirt and residual particles from the surface.

Sealing and Gland Configurations

To maintain high hygienic standards, the sealing elements used in the pump are also selected from FDA-compliant materials. The double-flushed cartridge mechanical seal creates a reliable barrier even in sticky, high-sugar products like jam and molasses. This system ensures that cleaning fluid is directed in a controlled manner to the seal surfaces, automatically removing deposits in the seal area and rapidly reducing wear. Additionally, food-grade elastomer gaskets like PTFE or EPDM maintain their elasticity over a wide temperature range (–20 °C to +150 °C) and offer long-lasting sealing performance.

Ease of Hygienic Assembly and Disassembly

To expedite cleaning and maintenance processes in MIT Lobe Pumps, V-Clamp or Tri-Clamp connections are preferred. These types of connection elements offer quick assembly-disassembly without the need for tools and minimize the margin of error. The pumps are optimized to leave no dead volume—also known as "dead leg"—within the body. Internal corners are designed with radii; this regulates fluid flow and ensures that the CIP solution is evenly distributed across all surfaces.

Process Reliability and Validation

Throughout the entire production process, design verification tests are conducted with reference to FDA Title 21 CFR Part 177 compliance and 3-A Sanitary Standards. After part manufacturing, surface roughness measurements, sealing tests, and resistance trials against biofilm formation are conducted, and each pump is approved before being sent to the field. These validation steps guarantee the uninterrupted fulfillment of GMP (Good Manufacturing Practices) and HACCP (Hazard Analysis and Critical Control Points) standards on the production line.

In conclusion, the FDA-approved hygienic design of MIT Lobe Pumps ensures reliable and uninterrupted operation of food and beverage processes in all details, from material quality to surface workmanship, sealing to ease of assembly.

Flexibility Provided by Positive Displacement

The positive displacement operating principle constitutes the most important difference of lobe pumps compared to other pump types. Thanks to this principle, the pump carries a predetermined, fixed volume in the suction and discharge chambers with each revolution. As a result, whether the fluid's viscosity is a thin liquid at a few centipoise levels or a dense paste-like substance above tens of thousands of centipoise, the displacement feature keeps fluctuations and leaks in the flow rate to a minimum. Thus, the pump's performance is not affected by changes in viscosity or fluctuations in line length and pressure differences.

This volumetric accuracy provides a critical advantage, especially in applications where process control requires precision. For example, a single lobe pump model can transfer both low-strength aromatic oils and sticky products like high-density jam or glucose syrup with the same settings. Process engineers can achieve standardization on a single pump family without the need to add additional pump types in different parts of the line. This reduces maintenance stock diversity, shortens maintenance times, and significantly lowers operating costs.

The bidirectional operating capacity provides extra flexibility to the operator. In situations requiring line cleaning or reverse flow, the pump continues to operate by changing direction without any modification. This eliminates the need for a separate circuit pump for line filling operations during commissioning. Additionally, since wear in the reverse direction is distributed equally, it contributes to balanced wear on the seal and rotor surfaces.

Positive displacement lobe pumps protect sensitive formulations with low shear rates. Fluids with microbiological or chemical sensitivity are transported without being exposed to high shear forces, reducing the risk of deterioration in the molecular structure or particle integrity of the product. This situation guarantees quality consistency, especially in pharmaceutical and food formulations containing emulsions, suspensions, or particles.

Finally, the positive displacement principle also positively reflects on energy consumption and control capabilities. When integrated with variable frequency drives (VFD), the pump's flow control exhibits an extremely linear character; the operator maximizes energy efficiency by making speed changes and can manage process parameters with fine-tuning in real-time. Thus, lobe pumps stand out as an innovative solution that meets flexibility, precision, and sustainability goals together.

Customization Opportunities for Your Process

Capacity and Pressure Range

The MIT Lobe Pump family is designed to operate across a wide flow range of 0–65 m³/h, bringing together low, medium, and high-capacity process needs on a single platform. This range covers a wide spectrum from small-volume dosing operations to medium-scale production line filling-discharging applications. The actual performance characteristic of the pump is verified with unique pump curves (Q–H curves) prepared before manufacturing; thus, it is guaranteed that each series will work perfectly at the flow point requested by the customer and under the back pressure conditions in the line.

The maximum pressure resistance of up to 16 bar offers seamless operation, especially in high-pressure transfers or long-distance pipelines. The pump casing and gearbox are subjected to strength tests suitable for this pressure level, making them resistant to mechanical stresses and vibrations that may occur during operation. In addition to pressure resistance, seal and gasket systems are selected to withstand 1.2–1.5 times the standard test pressure, ensuring operational safety and sealing in the long term.

When determining the specific flow and pressure needs for your process, parameters such as total dynamic head loss (TDH) in the line, fluid viscosity, temperature changes, and potential gas phase formation (NPSH) are calculated in detail. In light of this data, the pump's gear ratio and drive motor power are optimized in terms of both cost and energy efficiency. In facilities requiring advanced control solutions, the integration of variable frequency drives (VFD) is recommended; the operator can reduce energy consumption and respond instantly to sudden process changes by making speed and torque adjustments in real-time during production. This ensures that the MIT Lobe Pump offers high performance and long-term reliability in both stable operating conditions and dynamic production processes.

Rotor Geometry and Flow Dynamics

The rotor geometry, which forms the heart of lobe pumps, plays a critical role in fully adapting to the fluidity characteristics of the product and process requirements. The two-lobe rotor configuration is particularly preferred in mixtures with high solid content such as jam, molasses, or fruit puree; wide passage channels allow for the smooth transport of large particles while also achieving a homogeneous flow profile. This structure minimizes the risk of clogging, balances the compression force of the dense fluid in the lobe gaps, and thus facilitates the control of both flow rate and pressure fluctuations.

Three-lobe designs, on the other hand, create smaller gaps between rotor surfaces, standing out in applications requiring precise pressure distribution and low vibration. This rotor type reduces the shear force on the fluid thanks to more frequent lobe movements, while also keeping vibration values to a minimum. As a result, the chemical and physical structure of high-value cosmetic creams or pharmaceutical emulsions with high shear sensitivity is preserved during transfer. Additionally, the three-lobe configuration significantly reduces internal leaks; this means high efficiency and energy savings.

Butterfly rotor models are ideal for oil-based emulsions or liquid-oil mixtures requiring a thin film layer. This design increases the rotor surface area while keeping pressure losses low; the fluid passes through the lobe gaps at high speed, minimizing the shear effect. Thus, the sensitivity of food additives and aroma solutions, where particle size is critical, is preserved. The single butterfly rotor provides an advantage, especially in CIP (Clean-In-Place) and SIP (Sterilize-In-Place) processes; minimal dead volume ensures that cleaning solutions and steam reach every point inside the pump, easily meeting hygiene conditions.

Each rotor option is produced under micron-level tolerance control using CAD and CNC machining technologies. Fluid Dynamics simulations (CFD) conducted during the production phase are used to determine the ideal geometry of the lobe gaps; formulations that minimize hydraulic losses are developed by analyzing the speed and pressure distribution of the fluid around the lobe. Thus, both stable flow in low-viscosity liquids and clog-free transfer in high-viscosity pastes are guaranteed. As a result, the correct rotor selection and precise workmanship ensure that the MIT Lobe Pump family offers superior performance and long life in every process.

Materials and Surface Coatings

One of the cornerstones of the long-lasting and safe operation of lobe pumps is the quality of the materials chosen for all components in contact with the fluid. The MIT Lobe Pump design primarily uses AISI 316L stainless steel; this alloy provides superior resistance to chloride ions, acidic solutions, and general corrosion due to its high chromium and molybdenum content. The tight casting and forging processes conducted at the micro-level within the stainless steel structure minimize the porosity rate of the material, eliminating the risk of acidic or abrasive agents penetrating the surface and damaging the metal matrix.

In food, cosmetic, and pharmaceutical applications, preventing microbial contamination is of critical importance. Therefore, the roughness value of the internal surfaces is reduced to Ra ≤ 0.8 µm. The micron-scale polishing process ensures that the surface becomes completely homogeneous, preventing the accumulation of bacteria or product residue in micro-cracks and indentations. Alternatively, the electropolishing process both polishes the metal surface and strengthens the chromium oxide passive layer of stainless steel; this increases durability and allows cleaning fluids to easily slide off the surface during CIP (Clean-In-Place) and SIP (Sterilize-In-Place) processes, removing all residual materials.

When abrasive and hygroscopic fluids are involved, situations requiring more resistance than standard steel arise. MIT offers carbide-coated or special nickel-chromium-boron alloy materials on rotor hubs and seal surfaces for these types of heavy-duty conditions. Carbide coatings minimize friction occurring at high-speed and pressure points inside the pump, preventing abrasive particles from damaging the rotor surface. Special alloy core parts provide an additional barrier against chemical attacks; these layers make a critical difference, especially for lines working with acidic syrups, alkaline solutions, or organic solvents.

The exterior body of the pump is supported by different coating options depending on field conditions. Epoxy-based multi-layer protective coatings are preferred against the risk of corrosion caused by impact, vibration, and humid environments in industrial facilities. Epoxy resin forms a strong chemical bond with the metal surface, blocking external factors. In projects requiring higher UV or chemical resistance, polyurethane-based coatings reduce the risk of cracking and peeling with their elastic structures. These coatings minimize both general dimensional stability and color fading, preserving the equipment's field performance for a long time.

Each pump unit undergoes detailed surface control tests after production. Tolerance is verified through roughness measurements, coating thickness controls, and microstructure examination conducted on a part basis. This process guarantees the complete compatibility of every MIT Lobe Pump sent to the field in terms of both mechanical strength and hygienic standards. As a result, these advanced applications in material science and surface treatments ensure that your pump delivers superior performance in challenging process conditions and offers long-term reliability and ease of maintenance.

Connection and Installation Flexibility

To facilitate installation and quickly adapt to changes in the line, selections are made between threaded, flanged (DIN, ANSI), and food-grade Tri-Clamp fittings. Side, top, or bottom inlet-outlet configurations are defined as needed to optimize pipe routing. Pre-mounted pressure gauge and thermometer ports on the pump body provide the opportunity to monitor and record process parameters instantly.

Automation and Monitoring Integration

In Industry 4.0 compatible projects, PLC or SCADA integration is carried out into pump control panels. Sensors monitoring flow rate, pressure, temperature, and seal condition transmit data to remote monitoring systems, allowing you to predict potential failures. Recorded data optimizes maintenance periods, increasing process sustainability.

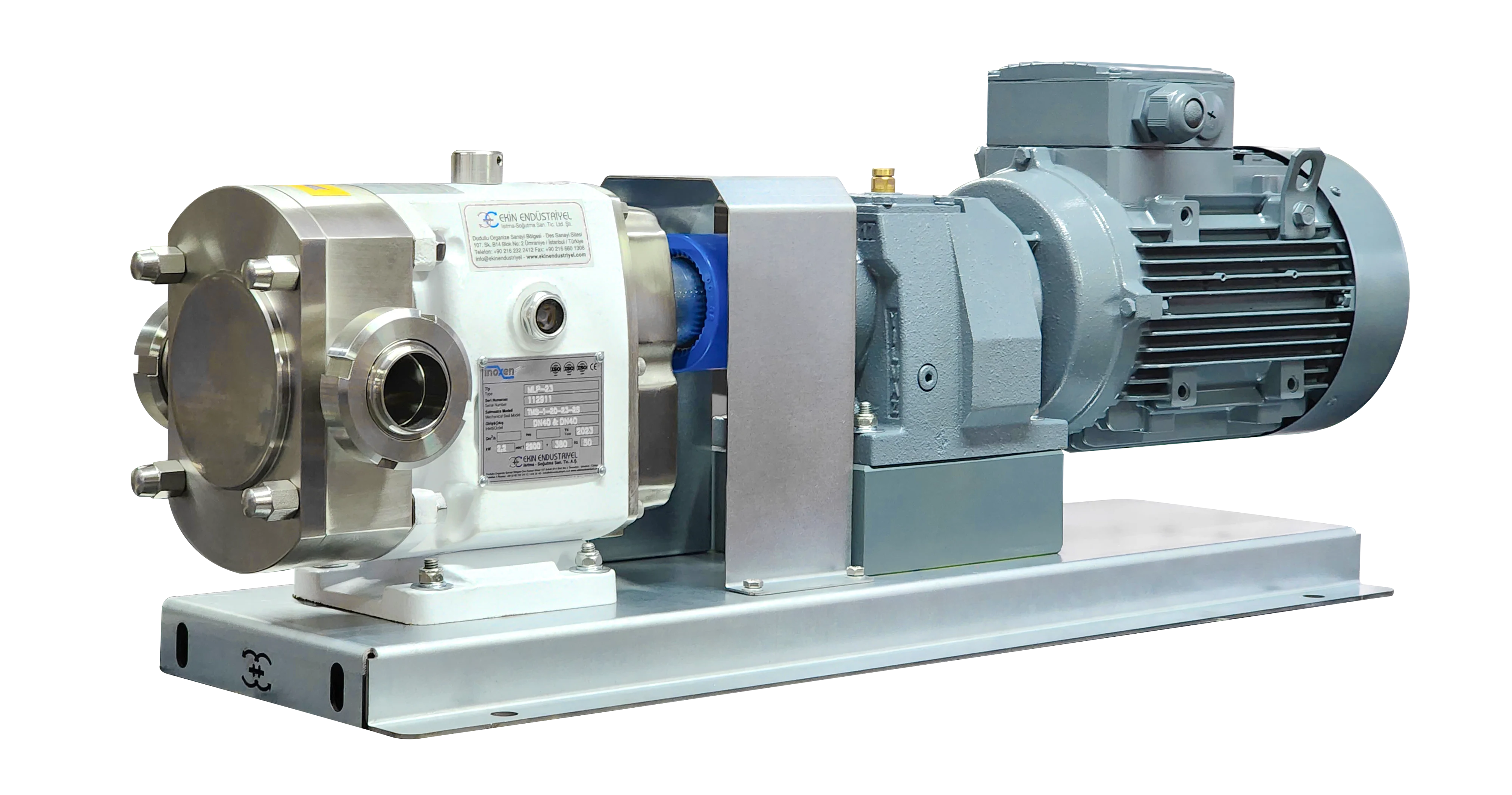

Mobile and Skid Mount Solutions

Units delivered on wheels or fixed skids for workshop or field operations are offered with fully assembled panels, control buttons, and energy connection boxes. This shortens commissioning time and minimizes transportation and installation costs.

At every stage, MIT engineers accelerate the process with 3D modeling and prototype approval; they stand by you from the day of technical data collection to production approval to design the most suitable lobe pump configuration for your process.

Easy Installation, Maintenance, and Durability

Thanks to its mechanical simplicity and modular design approach, the MIT Lobe Pump can be commissioned in minutes instead of hours during field installation. The pump's body parts are interlocked with V-Clamp or Tri-Clamp type quick connection clamps; thus, parts can be easily disassembled and reassembled without the need for special tools. Pre-aligned pipe fittings and integrated sag adjustment feet during assembly minimize pipe line vibrations while ensuring that the pump axis is maintained correctly under all conditions. Mobile models offered with a fixed or wheeled chassis on a skid are ideal for both field transport and quick transitions between different lines, thanks to lightweight articulated connection points.

Maintenance processes are of critical importance, especially in facilities with continuous production. In MIT Lobe Pump, the mechanical seal unit is designed with a cartridge system that can be replaced without removing the body cover. Thus, sealing elements can be renewed in a few minutes without the need to intervene in lubrication mechanisms. Since the rotor set and gearbox are also located on pre-mounted floating bearings, parts can be easily repositioned by referring to drawings and labels. All spare part varieties are offered in a "maintenance kit" specially prepared for the pump; this shortens stock management and response time to urgent repair needs.

In terms of durability, the gearbox, which plays a critical role in the pump, is strengthened against corrosion and impacts by applying an epoxy-based protective coating to the cast iron body. In parts exposed to abrasive chemicals or high temperature differences, carbide-coated gears and high-performance alloy seal materials are used. The optional heating jacket eliminates the risk of freezing by maintaining product fluidity in low-temperature environments, while thermal stability keeps pump efficiency constant. The pump's quiet operation feature, combined with vibration-damping feet and balanced rotor design, increases operator comfort and prevents possible resonance effects on surrounding equipment.

All these installation, maintenance, and durability improvements make the MIT Lobe Pump attractive for both new investments and modernization projects. Minimizing operational interruptions, reducing maintenance costs, and ensuring plant production continuity are the tangible benefits the pump provides in both the short and long term.

Use of Lobe Pumps in Various Sectors

The first step in the MIT Lobe Pump design process is the meticulous analysis of the customer's process data. The pump's gear ratios and motor power are determined by considering the targeted flow range, total pressure loss in the line, and operating temperature. Offering solutions that can be integrated with variable frequency drives (VFD) within the 0–65 m³/h capacity band minimizes energy consumption while maintaining fluid flow stability. This allows both low-viscosity liquids and dense products like jam-molasses to be transported without problems with a single pump configuration.

AISI 316L stainless steel is used as the basis for all surfaces in contact with the fluid; optionally, internal surface roughness is reduced to Ra ≤ 0.8 µm through micron-level polishing or electropolishing processes. To increase wear resistance under challenging conditions, carbide or special alloy coatings are used on rotor and hub parts. This material selection ensures full compliance with food-pharmaceutical hygiene standards and offers a long-lasting operation guarantee. The process of adapting to the pipe installation is accelerated thanks to DIN, ANSI flanged, or Tri-Clamp fitting options at connection points; V-Clamp type quick assembly systems allow maintenance and CIP operations to be performed without the need for hand tools.

Pump units delivered on mobile or fixed skids are shipped to the field with pre-assembled control panels and energy distribution boxes; thus, installation time is shortened, and commissioning tests are quickly completed. Sensor integrations compatible with PLC and SCADA systems offer the opportunity to monitor flow rate, pressure, and temperature data instantly; past operation records are used to optimize maintenance periods. During the prototype approval phase, 3D model shares and virtual assembly simulations are conducted, followed by performance and hygiene tests on a sample unit for field tests. All these stages guarantee that your pump fits perfectly into your process and maximizes your operational efficiency.

Conclusion and Future Perspective

Lobe pumps offer a groundbreaking standard in industrial fluid transfer with their positive displacement operating principle, which enables high-accuracy volumetric transfer, hygienic material selection, and personalized design opportunities. The MIT Lobe Pump family can be used across a wide range, from low-viscosity liquids to high-density paste-like products, adapting to every sector and process; it also meets the strictest hygiene requirements in food, chemical, and pharmaceutical facilities. This diversity provides plant operators with the advantage of reducing stock and maintenance costs while achieving continuity and uninterrupted performance in operation. Therefore, MIT Lobe Pumps are considered not just a pump solution but a strategic investment tool that increases long-term operational efficiency.

Looking to the future, the importance of digital transformation and the Smart Plant concept in the industry is increasing. Sensor technologies to be integrated into MIT Lobe Pump systems will allow real-time monitoring of critical parameters such as pressure, flow rate, temperature, and seal condition. This will enable operators to continuously monitor pump performance via remote monitoring platforms, optimize planned maintenance processes through early detection of potential deviations, and minimize downtime. Industry 4.0 compatible automation solutions will combine pump speed control with AI-supported algorithms, reducing energy consumption while maintaining process stability at a high level.

Additionally, in line with sustainability goals, new gasket materials and mechanical seal technologies that minimize lubrication requirements and internal leaks are being developed in the design of MIT Lobe Pumps; environmentally friendly production methods that will reduce environmental impact are being popularized. These steps will both reduce the carbon footprint of facilities and lower total operating costs by extending the lifespan of maintenance materials. In future process lines, lobe pumps will not only remain a transfer tool but will also form the core component of an integrated "smart fluid management" platform with data-driven maintenance strategies and energy management systems. Thus, the MIT Lobe Pump family will continue to be an innovative leader guiding the industry in efficiency, sustainability, and technology integration.