In industrial facilities, energy expenses stand out as one of the most critical components of operating costs. Therefore, businesses are turning to solutions that minimize energy losses while increasing process efficiency. Economizers are strategic equipment that comes into play at this point. By recovering heat released from waste gases or process fluids and making it reusable, economizers provide energy efficiency and contribute to reducing environmental impacts.

In modern manufacturing, sustainability has become an indispensable criterion from both economic and environmental perspectives. The recovery mechanism offered by economizers allows businesses to reduce their carbon footprint, lower energy costs, and optimize resource usage. The conversion of waste heat into usable energy presents significant savings potential, especially in industries operating at high temperatures.

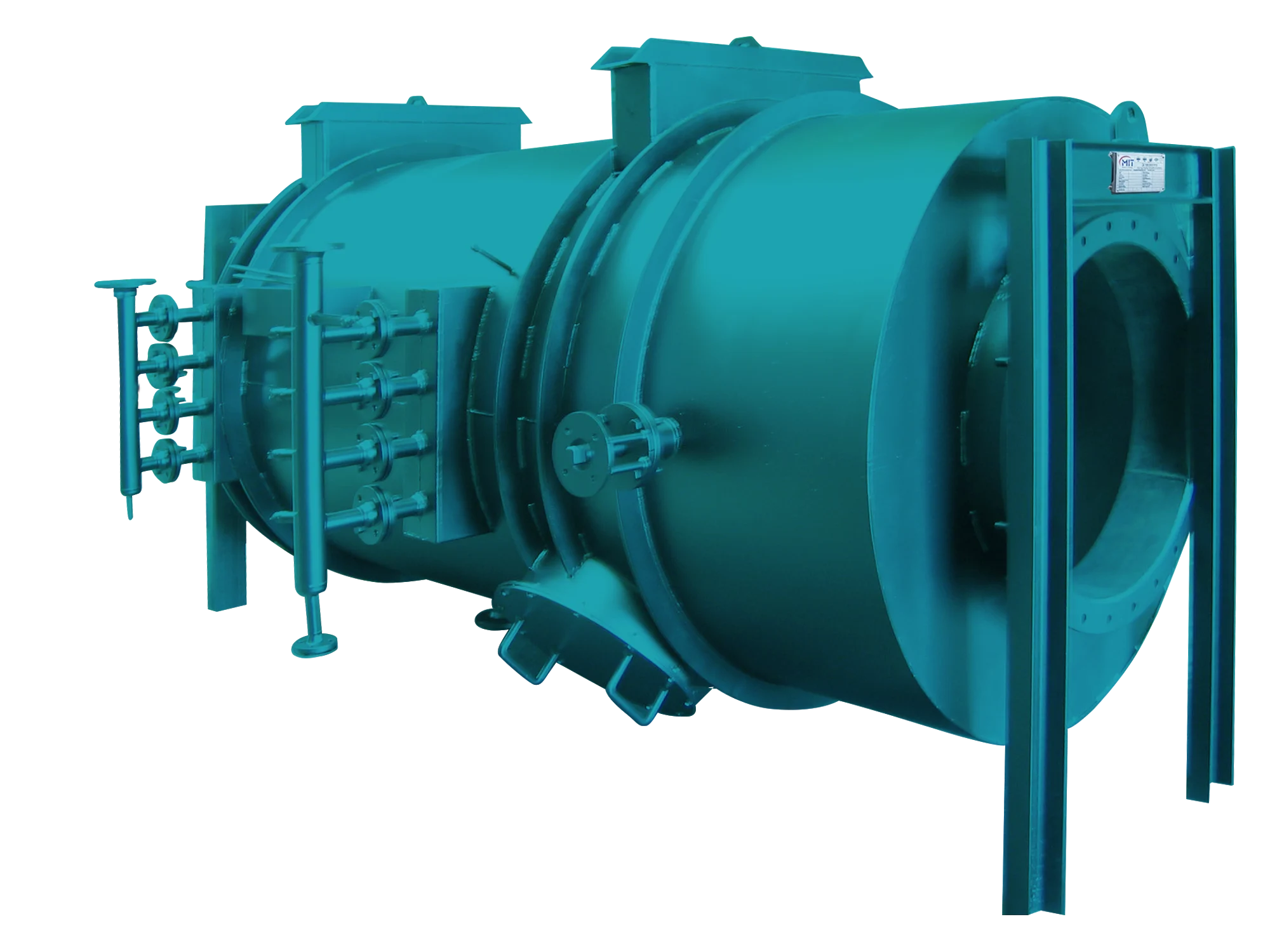

Another reason for the widespread adoption of economizers in the industry is their ability to be easily integrated into production lines with technological advancements. These systems, which can be designed with various capacities, different material types, and according to process needs, have a wide range of applications from small-scale businesses to large energy production facilities. Thanks to their design flexibility, they can be adapted to the unique operating conditions and process requirements of each facility.

These energy efficiency-focused devices not only improve existing heat recovery systems but also provide a structure that reduces maintenance costs in the long term and stabilizes production processes. By using this technology, businesses gain a competitive advantage and achieve sustainable production goals more quickly.

The advantages offered by economizers make them indispensable equipment in many industrial fields. In the following sections, we will discuss in detail how economizers are used in various sectors and the benefits they provide to these sectors.

The waste heat generated in industrial facilities is often a valuable energy source that is released into the atmosphere without being utilized. Heat recovery systems provide efficiency by reintroducing this energy back into the process and significantly contribute to reducing operating costs. Economizers are one of the most critical pieces of equipment at the center of these systems. They recover the heat contained in waste gases, making it usable for steam production, hot water supply, or process heating applications.

The primary goal of heat recovery is to utilize existing energy resources in the most efficient way. Economizers lower flue gas temperatures, re-circulating usable heat within the system. This energy can be used in heating or steam production processes according to the different needs of the business, thus achieving a significant reduction in total energy consumption. Especially in systems operating at high temperatures, heat recovery offers a solution that can pay for itself in a very short time.

Economizers used in heat recovery systems are designed with special materials and pipe configurations according to the operating conditions of the facility. While stainless steel is preferred in condensing applications, finned tube technologies come to the forefront in processes with lower temperature differences. This variety allows for flexible solutions suitable for different industrial needs.

The use of economizers in heat recovery systems not only provides energy savings but also supports environmental sustainability. Lower fuel consumption means less carbon emissions. This provides a significant advantage, especially for businesses with environmental goals. Additionally, increased system efficiency contributes to achieving a more stable and reliable performance in production processes.

In conclusion, the use of economizers in heat recovery systems is an investment that offers significant benefits from both economic and environmental perspectives. It creates a more sustainable structure for businesses where energy resources are used more efficiently, costs are reduced, and production processes are optimized.

Providing Energy Efficiency in Industrial Boiler Systems

Industrial boilers are essential equipment that consume large amounts of energy in production facilities and ensure the continuity of the process. The waste gases generated in these systems are usually at high temperatures and carry significant heat potential. Economizers are used to evaluate this potential and increase the efficiency of boiler systems. By recovering the energy lost in flue gases, they preheat the feed water or process fluids, helping boilers perform better with less fuel.

The use of economizers in industrial boilers directly reduces fuel consumption, thereby lowering operating costs. Preheating the boiler feed water increases combustion efficiency and reduces the amount of energy needed when the boiler starts up. This results in a more stable operation of the system and supports the longevity of the equipment by reducing wear and tear. The savings effect provided by economizers becomes even more pronounced in facilities using high-capacity boilers.

There are various economizer designs for different boiler systems. Finned tube economizers are preferred in areas requiring high heat transfer, while non-finned economizers offer advantages with their easy-to-clean structure in processes with a higher risk of fouling. Condensing economizers aim for maximum efficiency by recovering the additional energy released from the condensation of moisture in flue gases. This variety allows for the easy integration of economizers into different types of boilers across various sectors.

The use of economizers in boiler systems not only creates economic benefits but also results in environmental gains. Since lower fuel consumption means fewer emissions, businesses can significantly reduce their carbon footprint. Additionally, lower exhaust temperatures decrease the amount of heat released into the environment, minimizing environmental impacts. This situation creates a significant advantage for businesses that operate in line with sustainable production goals.

As a result, the use of economizers in industrial boiler systems is a strategic application that both increases efficiency and reduces operating costs. Thanks to energy recovery, the performance of boilers improves, operational continuity is supported, and environmental impacts are minimized.

The Importance of Economizers in Energy Production Facilities

Energy production facilities are critical operations where systems operating at high temperatures are heavily utilized, significant amounts of fuel consumption occur, and direct energy conversion takes place. The waste gases generated in these facilities carry a significant amount of thermal energy. Economizers have established a critical place in energy production infrastructures as one of the most effective ways to recover this energy. Utilizing waste heat not only reduces fuel consumption but also contributes to lowering energy production costs and increasing system efficiency.

Since the boilers, turbine systems, and combustion chambers used in power plants operate at high temperatures, the flue gas exit temperatures are also quite high. Economizers recover the energy contained in these gases, making it usable for feed water, process fluids, or heating circuits. This reduces fuel consumption and uses fewer resources to produce the same amount of energy. Each unit of recovered energy directly provides economic benefits to the operation by increasing the overall efficiency of the facility.

Another significant advantage of using economizers in energy production facilities is the reduction of emissions. The decrease in fuel consumption leads to a reduction in carbon dioxide and other harmful gases released into the atmosphere. This situation is a significant advantage, especially in countries with strict environmental regulations. Economizers help reduce the carbon footprint in facilities aiming for sustainable energy production and facilitate compliance with environmental standards.

The economizers used in these facilities are produced with materials resistant to high temperatures and harsh operating conditions. Condensing economizers demonstrate resistance to corrosive effects thanks to their stainless steel structures, while large-capacity double-row or modular economizers ensure maximum efficiency in high-flow systems. This diversity allows power plants to be equipped with solutions suitable for different process needs.

Stability and sustainability are among the most critical elements in energy production facilities. Economizers contribute to making these systems more reliable, efficient, and economical. Recovering waste heat not only enhances facility performance but also helps reduce production costs. Thus, energy production facilities achieve a more sustainable structure both economically and environmentally.

Economizers for Process Efficiency in the Chemical and Pharmaceutical Industry

The chemical and pharmaceutical industry stands out with complex process structures, high-temperature requirements, and precise production conditions. Energy use in this sector is quite intensive, and the continuity and accuracy of processes are of great importance. Economizers play a critical role in chemical and pharmaceutical facilities as heat recovery equipment that directly contributes to these requirements. Making waste heat reusable reduces production costs and helps enhance process safety.

Various reactions, distillation processes, drying systems, and steam lines in chemical and pharmaceutical facilities consume high amounts of energy. The waste gases generated during these processes contain significant amounts of thermal energy. Economizers enable the recovery of this energy for use in hot water production, heating process fluids, or preheating boiler feed water. Thus, the overall energy efficiency of the facility significantly increases, providing higher production capacity with lower fuel consumption.

The challenging production environment of the chemical and pharmaceutical industry requires high durability and precise engineering in the equipment used. Therefore, the materials used in economizers are selected to withstand corrosive gases, high temperatures, and aggressive chemical environments. Stainless steel or special alloys are often preferred in condensing economizers. Finned or unfinned tube designs are applied according to the process's contamination situation and heat transfer needs. This customizable structure offers economical and reliable use.

Energy efficiency in these sectors not only provides cost advantages but also supports environmental sustainability. Reduced fuel usage leads to lower emissions, and production processes become more environmentally friendly. Additionally, a stable heat balance contributes to maintaining product quality by preventing sudden temperature changes in the process. This is of great importance in sectors like pharmaceutical production, where tolerance for errors is minimal.

In conclusion, economizers are a strategic solution that optimizes energy consumption, increases process reliability, and facilitates businesses in achieving their sustainability goals in the chemical and pharmaceutical industry. Thanks to their flexible designs suitable for the complex structure of this sector, they provide both efficiency and cost advantages in production processes.

Hygiene and Energy-Saving Focused Use in the Food and Beverage Industry

The food and beverage industry is a sector where hygiene standards must be maintained at the highest level, while also involving energy-intensive processes such as continuous heating, boiling, pasteurization, and cleaning. Therefore, energy costs occupy a significant place in the production budget. Economizers provide energy savings and support sustainable production processes by offering hygienic and efficient heat recovery solutions suitable for the needs of this sector.

The amount of water and steam used in food production processes is quite high. Pasteurization lines, fermentation tanks, boiling boilers, and washing systems require continuous hot water and controlled heat. The waste gases released during production contain a high amount of usable energy. Economizers recover this energy for use in hot water production or process preheating. This reduces fuel consumption and ensures more stable temperature control in production lines.

In the food and beverage industry, hygienic design is essential. Therefore, the preference for stainless steel surfaces in condensing economizers not only provides corrosion resistance but also reduces the risk of bacterial formation. Thanks to their easy-to-clean structures, they can work integrated with CIP (Clean-in-Place) systems, thus maintaining hygiene without interrupting production lines. These features make economizers an ideal solution to meet the industry's strict hygiene requirements.

Energy savings not only create a cost advantage in food production but also hold great importance within sustainability goals. The reduced fuel consumption through economizers also lowers carbon emissions. This situation supports both the social responsibility and regulatory compliance processes of companies aiming for environmentally conscious production.

The use of economizers in food and beverage facilities ensures that production processes are carried out more efficiently and precisely. Achieving the required temperature more quickly increases production continuity while preventing sudden temperature changes, thus preserving product quality. These features provide significant advantages, especially in sensitive processes such as dairy products, fruit juice, beer, carbonated beverages, and ready-to-eat food production.

As a result, economizers have become a fundamental component in the food and beverage industry in terms of both hygiene and efficiency. These solutions, which reduce energy costs while increasing product quality and production safety, are an indispensable part of modern food production.

Applications of Economizers in High-Temperature Environments in Oil and Gas Facilities

Oil and gas facilities are critical production areas where processes operate under high temperature and high pressure, with extremely high levels of energy consumption. The waste heat generated in refineries, natural gas processing plants, and petrochemical complexes offers significant energy savings potential when recovered with the right equipment. Economizers become a fundamental part of energy management by providing durable and efficient solutions tailored to the requirements of these challenging environments.

In the oil and gas sector, waste heat is released from combustion systems, furnaces, turbines, and process fluids. This heat often reaches very high temperatures and is an ideal source for energy recovery. Economizers make this energy available for reuse in areas such as steam production, feedwater heating, or preheating process fluids. Thus, fuel consumption is significantly reduced, and a more stable heat balance is achieved in production lines.

One of the most notable features of this sector is that process fluids often contain corrosive and aggressive chemical components. Therefore, the materials used in economizers are selected from special alloys that provide high-temperature resistance and corrosion resistance. In condensing economizers, stainless steel and nickel-based alloys are prominent, while finned or non-finned designs are customized according to the structure of the process. This engineering approach ensures the long life and reliable operation of the equipment.

Increasing efficiency in oil and gas facilities is not only an economic necessity but also critically important for reducing environmental impacts. The energy savings provided by economizers reduce fuel consumption, which leads to a decrease in carbon emissions and other pollutants. The savings achieved, especially in large-scale refineries, are significant enough to contribute to global sustainability goals.

Another advantage that economizers offer to these facilities is the increased reliability of processes. More stable temperature values extend the lifespan of equipment and prevent failures that may arise from sudden temperature changes. This greatly contributes to maintaining operational reliability in the oil and gas sector, where continuity is critical.

In conclusion, the use of economizers in oil and gas facilities is an important strategic investment in terms of both resistance to high-temperature environments and energy efficiency. The effective recovery of waste heat supports long-term cost advantages for businesses while also reducing environmental impacts.

Advantages of Using Economizers in HVAC Systems

HVAC systems are widely used systems that meet essential climate control needs such as heating, cooling, ventilation, and hot water supply in both industrial facilities and commercial buildings. Energy consumption in these systems constitutes a significant share of total operating costs. Economizers are important components that reduce this energy consumption by recovering usable waste heat in HVAC applications, increasing system efficiency, and supporting sustainable building management.

Boilers, chillers, and ventilation units used in HVAC systems produce high-temperature exhaust gases while operating. Economizers recover the heat contained in these gases and return it to the system for use in hot water production, air preheating, or other heating needs. Through this energy recovery, HVAC systems can provide the same performance with less fuel, allowing businesses to achieve significant savings.

Energy efficiency in modern buildings is of great importance from both economic and environmental perspectives. The use of economizers reduces the carbon footprint of HVAC systems; because less fuel consumption means lower emissions. At the same time, buildings with high energy efficiency gain significant advantages for sustainability certifications (such as LEED, BREEAM). This makes the use of economizers even more valuable in large facilities, hotels, hospitals, and shopping centers, which have high energy consumption.

Economizers used in HVAC applications typically have a compact design that facilitates maintenance and can be easily integrated into existing systems. Especially, condensing economizers achieve high efficiency even at low exhaust temperatures, reducing hot water production costs. Finned tube technologies provide effective heat transfer at high air flow rates. This allows for the selection of the most suitable economizer design based on the building type, usage purpose, and system capacity.

In addition to energy savings, another important contribution of economizers to HVAC systems is comfort improvement. More stable heating and hot water production increases users' comfort levels and ensures that system performance is more predictable. Additionally, it offers operational advantages such as longer equipment life and reduced maintenance needs for businesses.

As a result, the use of economizers in HVAC systems is an ideal solution that increases energy efficiency, reduces operating costs, and supports environmental sustainability. Thanks to its design suitable for the dynamics of this sector and its long-term advantages, it has gained significant importance in modern building management.

Economizer Solutions Suitable for Harsh Conditions in the Maritime Sector

The maritime sector has a quite challenging working environment, ranging from the corrosive effects of saltwater to high humidity levels, continuous vibrations, and variable temperature conditions. Ship engines, boiler systems, and auxiliary machines continuously produce energy, generating a large amount of waste heat during these processes. Economizers stand out as an important solution that recovers this waste heat, allowing ship systems to operate more efficiently, economically, and environmentally friendly.

Ship engines consume a high amount of fuel, especially on long voyages, and exhaust gases carry significant levels of thermal energy. Economizers come into play to recover this energy and are typically used to heat boiler feed water, produce hot domestic water, or provide heat for onboard processes. This not only reduces fuel consumption but also significantly lowers the operational costs of ships. The savings achieved, especially in ships engaged in long-distance cargo transportation, contribute greatly to total operating costs.

One of the most important requirements of maritime applications is durability. Therefore, materials used in economizers suitable for marine environments are selected from stainless steel or special alloys that offer high corrosion resistance. In applications where condensation risk is present, special coatings are used to enhance the equipment's resistance to aggressive external factors such as saltwater and humidity. Thus, economizers provide a robust structure that can be safely used throughout the lifespan of the ship.

The need for hot water and steam in ship machinery is continuous. Economizers help meet these needs more stably. More stable temperature values ensure that onboard heating systems operate more efficiently, increase comfort in crew living areas, and maintain the performance of auxiliary systems. This is extremely valuable for conducting ship operations seamlessly and reliably.

The use of economizers in the maritime sector also has significant environmental contributions. Lower fuel consumption means lower emissions and helps ships conduct environmentally friendly operations. Especially with the tightening of emission standards set by the IMO (International Maritime Organization), the use of economizers has become more strategic today.

In conclusion, economizers in the maritime sector are an indispensable part of modern ship designs with their durability, energy-saving structure, and environmental advantages. Thanks to their production suitable for harsh marine conditions, they offer a long-lasting, reliable, and efficient energy management solution.

Use of Economizers for Process Continuity in the Automotive Industry

The automotive industry has a highly energy-intensive structure with production lines requiring high precision, continuously operating painting and coating systems, drying ovens, testing lines, and metal processing processes. In these facilities with high production capacity, the uninterrupted continuation of processes is crucial for both energy efficiency and operational continuity. Economizers position themselves as an effective solution in the automotive sector to meet these requirements and enable the recycling of waste heat generated during production processes.

Many stages in automotive production lines are carried out with temperature-controlled systems. Painting ovens, coating lines, metal forming presses, engine testing systems, and pre-assembly processes require continuous hot water or heat at specific levels. The waste gases generated during these processes carry high energy potential. Economizers make this energy usable by recovering it for hot water production or preheating process fluids. Thus, both fuel consumption decreases, and the heat balance of production processes is maintained more stably.

In the automotive industry, efficiency is a critical factor not only for reducing costs but also for ensuring production quality and process stability. Economizers contribute to achieving high-quality surfaces, especially in painting and coating lines, by helping minimize temperature fluctuations. More stable temperature control reduces errors that may occur in production, lowers scrap rates, and enhances product quality.

Economizers used in this sector are designed to suit the intense structure of production areas and variable process requirements. Finned tube economizers offer high heat transfer, while finless designs are preferred in lines with a higher risk of contamination. Additionally, since ease of maintenance is important in automotive facilities, systems that are economical and easy to clean are highlighted.

The use of economizers in the automotive sector also has significant environmental benefits. Lower fuel consumption means lower carbon emissions, which facilitates automotive manufacturers in achieving their sustainability goals. Many global automotive brands today have set serious targets for reducing their carbon footprint in production facilities, and economizers directly contribute to these goals.

In conclusion, the use of economizers in the automotive industry provides a strategic advantage in terms of energy savings, production quality, and operational continuity. The recovery of waste heat generated in production lines enables facilities to become more efficient, economical, and sustainable.

Economizers for Heat Management and Efficiency Increase in the Metal Industry

The metal industry is a sector characterized by processes that require high temperatures, such as melting, casting, rolling, heat treatment, welding, and surface preparation. The furnaces, boilers, and heating systems used during these processes consume large amounts of energy and produce waste gases at high temperatures. Economizers stand out as an important solution in the metal industry, increasing process efficiency and reducing energy costs by recovering thermal energy from these waste gases.

Since the process temperatures in metal processing facilities are very high, the potential for waste heat recovery is also quite significant. Economizers utilize the hot gases from furnace exits or heat treatment lines to recover this energy for producing hot water, heating systems, or preheating process fluids. This recovery allows the facility to consume less fuel, reduces energy expenses, and enables production processes to be carried out more stably.

In the metal industry, efficiency is not only an economic advantage but also a critical factor that directly affects product quality. Temperature control is decisive for the durability, hardness, and structural properties of the product, especially in heat treatment processes. With economizers, more stable temperature values are achieved in processes, which enhances product quality while reducing error rates. Additionally, since sudden temperature fluctuations are prevented, equipment lifespan is extended, and maintenance costs are lowered.

The durability of economizers used in this sector is of great importance. They must be designed to withstand high temperatures, intense operating cycles, and the particulate load generated in metal processing processes. Finned tube systems are used in areas requiring high heat transfer, while cleanable designs without fins are preferred in processes with a high risk of contamination. In applications where condensation is effective, stainless steel and special alloys provide long-lasting use.

Today, metal production facilities are subject to stricter regulations regarding environmental sustainability. The energy savings provided by economizers help reduce carbon emissions and facilitate compliance with environmental standards. Lower fuel usage means a lower environmental impact, which creates a significant advantage in the global competitive landscape.

In conclusion, the use of economizers in the metal industry is a strategic engineering solution that enhances production quality and reduces energy costs. Optimizing heat management supports the transition to a sustainable production structure while economizers are one of the most effective recovery methods against the high energy intensity of the metal processing sector.

Energy Savings in Drying and Finishing Processes in the Textile Industry

The textile industry is one of the sectors with continuous production processes, high-temperature drying, and finishing operations that consume a lot of energy. A significant amount of thermal energy is used during the dyeing, washing, squeezing, drying, and subsequent finishing processes of fabrics. The hot waste gases generated during these processes offer significant savings potential when recovered with the right systems. Economizers are an ideal solution for re-evaluating this energy, providing significant advantages in terms of both cost and efficiency for textile facilities.

Drying machines and finishing lines are continuously operating equipment in textile production, thus producing hot air or steam at high temperatures. The exhaust gases from these systems contain a large amount of waste heat. Economizers allow this heat to be recovered for use in producing hot water or preheating processes. This way, businesses reduce their fuel consumption and contribute to faster and more stable operation of processes.

Temperature control is quite critical in textile production. The texture, color durability, and final quality of fabrics often depend on the heat applied. The use of economizers results in a more stable heat distribution in facilities, which directly contributes to production quality. Reducing temperature fluctuations in drying or finishing lines prevents potential defects in the fabric and lowers waste rates. This is a significant advantage in terms of both cost optimization and quality continuity.

Another important factor in the use of economizers in the textile sector is that production processes can involve high humidity and chemical loads. Therefore, it is critical for systems to be manufactured with durable materials for long-lasting use. The preference for stainless steel in condensing economizers provides both corrosion resistance and reduces maintenance requirements. Finned or non-finned tube designs are selected according to the characteristics of the process to achieve maximum efficiency.

Since energy costs have a significant share in total production expenses in the textile sector, the use of economizers provides businesses with a direct competitive advantage. Facilities that consume less fuel not only reduce carbon emissions but also find it easier to achieve environmental sustainability goals. Today, many large textile manufacturers emphasize the impact of energy recovery systems in their sustainability reports and are standardizing this technology.

In conclusion, the use of economizers in the textile industry is an important engineering solution that optimizes the high energy requirements of drying and finishing processes, enhances quality, and reduces total production costs. The re-evaluation of waste heat offers both economic and environmental benefits, enabling modern textile facilities to achieve their sustainability goals.